At Eurobike 2019 we did not only find the big players exhibiting their latest products, but also many exciting start-ups, newcomers and underdogs in the engine and battery segment: We took a closer look at their new concepts and tell you what they promise, what challenges some of the new concepts face and whether there’s a hot candidate for the mass market!

AMPRIO

German manufacturer Amprio, which is part of the Rheinmetall Group, is working on a motor prototype. Production is planned for 2021, which explains why there aren’t any test-bikes available yet. For the 2019 season, Amprio has developed a new display and app and has promised to shake the market with outstanding connectivity features, a quiet motor, a complete eBike system and an outstanding customer-oriented service system. The complete system comes with two different battery options. Detailed info regarding the motor has not yet been disclosed.

Dimensions: n/a

Weight: n.a

Nominal power: n/a

Battery: 2 different sizes

Torque: n/a

Motor already used by: –

More infos at: amprio.com

BAFANG

BAFANG M500

The Bafang M600 is the more powerful S-Pedelec version of the M500 motor. With a torque of 120 Nm and a nominal power of 500 W, it’s predestined both for the US market and eMTB pedelecs with a 45 km/h speed-limit. Despite the higher performance and thus higher “power consumption”, it shares the same batteries and displays with the M500 model. We’re curious to see if any manufacturers will choose the smaller 450 Wh battery over the big 600 Wh modell. Whilst the battery mounts on the frame are the same, the M600 motor has a much bigger cover. Austrian eMTB startup Ettention is already using the M600 motor on its bikes.

Dimensions: n/a

Weight: 3.3 kg

Nominal power: 250 W

Battery: 450 und 600 Wh / intern und extern

Torque: 95 Nm

Motor already used by: American Eagle

BAFANG M600

The Bafang M600 is the more powerful S-Pedelec version of the M500 motor. With a torque of 120 Nm and a nominal power of 500 W, it’s predestined both for the US market and eMTB pedelecs with a 45 km/h speed-limit. Despite the higher performance and thus higher “power consumption”, it shares the same batteries and displays with the M500 model. We’re curious to see if any manufacturers will choose the smaller 450 Wh battery over the big 600 Wh modell. Whilst the battery mounts on the frame are the same, the M600 motor has a much bigger cover. Austrian eMTB startup Ettention is already using the M600 motor on its bikes.

Dimensions: n/a

Weight: 3.6 kg

Nominal power: 500 W

Battery: 50 & 600 Wh / Internal & External

Torque: 120 Nm

Motor already used by: Ettention Bikes

More infos at: bafang-e.com

BMZ Drive Systems: 725 Wh V10 Intube battery

At this year’s Eurobike, BMZ Drive Systems presented a new compact 725 Wh Intube battery. The aim of the German manufacturer was to develop a most powerful battery with the smallest possible measurements. The new V10 Intube battery should have the same size as the new 625 Wh Bosch Intube. According to project manager Eric Bär, however, his engineers were able to squeeze an extra 100 Wh into the same space by rearranging the 40 Li-Ion 21700 cells. The new V10 Intube battery, which will be launched in summer 2020 at the earliest, will be compatible with BROSE, SACHS, and Shimano motors.

40 Li-Ionen Zellen (21700) – 36 V

Weight ar.und 3.950 g including cover (manufacturer’s specifications)

More infos at: bmz-group.com

COMP C19

For 2019, Czech brand COMP presented a prototype of its new C19 motor, which is designed to give eBike designers plnty of freedom with innovative frame designs. The COMP C19 is compatible with both 1x and 2x drivetrains and gives manufacturers the option of using either 36V or 48V batteries. The biggest advantage of the C19, however, are the small dimension (64 mm wide) and low weight (2.6 kg). In order to reduce the wear of the chain and sprocket, COMP integrates a GSGI system into the shift cable, which reduces the power output of the motor under shifting. In addition, the rider should be able to modulate the power decrease. The system should be suitable for city-eBikes, eRoad bikes and eMTBs. According to COMP, the motor has almost no internal resistance when decoupling at the threshold. The first prototypes will be ready for testing as early as April 2020 and production is planned for the second quarter of 2020. By mid next year we will probably know how the COMP C19 stands up against its very fierce competition.

Dimensions: 64 mm width

Weight: 2.6 kg

Nominal power: n/a

Battery: third party manufacturers

Torque: 60 Nm

Motor already used by: –

More infos at: compdrives.com

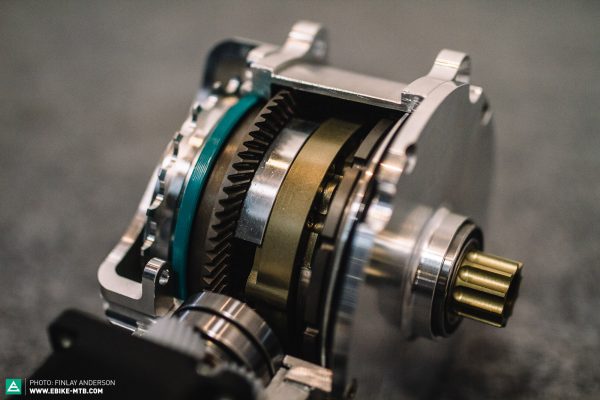

Kervelo Quartz

French brand Kervelo already introduced itsrevolutionary drive concept with integrated gearbox (4, 6 or 12 speed) back in 2018. The built-in gearbox eliminates the need for hubs or derailleurs and significantly reduces chain wear. For end-users this translates into less maintenance. Hold on: according to Kervelo, the first inspection service for the gearbox (oil change) is due at 10,000 km. The size of the motor including the gearbox, allows for shorter chainstays and a lower bottom bracket. In addition, the motor can be integrated deep into the frame to allow for a low centre of gravity. Due to the shape of the motor, however, the battery cannot be pushed all the way down into the down tube, which automatically pushes the centre of gravity back up. We’re dying to see what eBike designers will come up with to achieve an optimal weight distribution.

Both a chain- and belt-drive can be used to transfer power from the motor to the rear wheel. The small dimensions and the absence of a groupset make for a tidy look, which reminds us of a Bio-Fixie.

Whilst the 4-speed gearbox (Quartz 4) was designed for city- and urban-bikes, the 6-speed transmission (Quartz 6), which has a gear ratio of 323%, was developed for eGravel and eRoad bikes. The Quartz 12 is designed for eMTBs and provides a whopping 545 % gear-ratio over 12 speeds. At Eurobike 2019 we were able to admire the first hardtail with a Kervelo Quartz 12, which has already successfully completed 400 test kilometres. The first Quartz 4 motors will be shipped to a city-bike manufacturer in April 2020. Since Kervelo has a soft spot for DIY mechanics, it will make the system available for retail. Kervelo’s approach is revolutionary, the data are promising and we’re curious to see how the motor performs on the first test-bikes.

Kervelo Quartz 4

Dimensions: 133 mm width

Weight: 3.6 kg

Nominal power: 250 W

Bandwidth: 200 %

Battery: 330 Wh from Kervelo or custom

Torque: 70 Nm

Motor already used by: –

Kervelo Quartz 6

Dimensions: 133 mm width

Weight: 3.7 kg

Nominal power: 250 W

Bandwidth: 323 %

Battery: 330 Wh from Kervelo or custom

Torque: 70 Nm

Motor already used by: –

Kervelo Quartz 12

Dimensions: 147 mm width

Nominal power: 250 W

Bandwidth: 545 %

Battery: 330 Wh from Kervelo or custom

Torque: 70 Nm

Motor already used by: test bike with 400 km

More infos at: kervelo.com

Metz

Metz means “Made in Germany” – and they make both the software and the hardware. The German company has been in the electronic business for eighty years and wants to use its experience to guarantee fast delivery and short maintenance times. Despite having just two functioning eBike prototypes, Metz claims that its motor is ready for production and that some bike manufacturers have already shown interest. According to Metz, the first bikes will be produced in 2020. The motor will be available in three versions with respectively 55, 65 or 85 Nm of Torque, which makes them suitable for pretty much all eBike applications. The (very bright) Metz display and control panel form a solid, visually pleasing unit. Will Metz be able to shake up the eBike motor market next year? We’ll see!

Dimensions: 20 x 13 x 10 cm

Weight: 2.8 kg

Nominal power: n/a

Battery: n/a

Torque: 55, 65 or 85 Nm

Motor already used by: –

More infos at: metz-mecatech.de

MPF Drive: MPF 6

The MPF acronym stands for “More Power Feeling”, which also happens to be the corporate goal of the Austrian-Taiwanese cooperation. The MPF6 is characterised by a oil-lubricated metal gearbox and a water/dust-tight housing, which distinguish the motor from the competition. Whilst the MPF isn’t exactly light, the metal gearbox and the constant lubrication (around 200 ml oil bath) allow for a virtually silent and vibration-free operation and drastically reduce the maintenance intervals.

Dimensions: n/a

Weight: 4.2 kg

Nominal power: 250 W

Battery: external manufacturer

Torque: 90 Nm

Motor already used by: Greyp G6, E-LOM

More infos at: mpfdrive.com

OLI eBike Systems: OLI Sport

OLI is based in the Italian “Motor Valley” and, according to the manufacturer’s own statements, the world’s largest producer of industrial vibration motors. Whilst until recently their eBike systems were mainly known in Italy, the new Bianchi eMTB models presented at this year’s EUROBIKE, will put the Italian brand on the map. In their mid-price segment, cult brand Bianchi has already replaced the Bosch drive with an OLI sports motor.

Dimensions: 120 mm width

Weight: 3.5 kg

Nominal power: 250 W

Battery: external manufacturer, z. B. Phylion 500 Wh

Torque: 85 Nm

Motor already used by: Bianchi T-Tronik Rebel and T-Tronik Sport, Olympia EX900

More infos at: oli-ebike.com

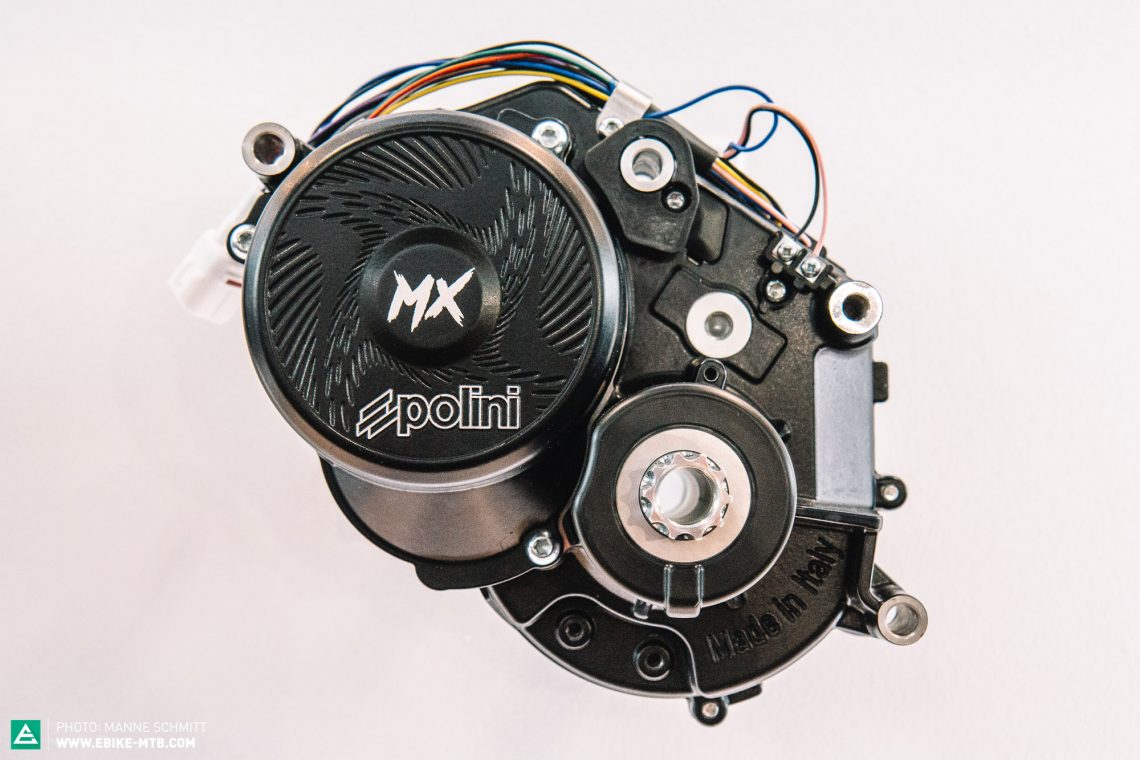

Polini Motori: Polini E-P3 MX

In 2016, the Italian manufacturer of mini motorcycles and motorcycle parts from Bergamo expanded its product portfolio and presented their first eBike motor, the Polini E-P3. This produces 70 Nm of torque and is currently used by a number of small Italian bike manufacturers. For the 2020/21 season, Polini wants to introduce the 90 Nm E-P3 MX motor as an update of the existing motor. The power increase also implies a slight weight increase of approx. 130 g. The dimensions of the housing will be identical, which means the existing frame mounts can be maintained.

Dimensions: 14.4 mm width

Weight: 2,980 kg

Nominal power: 250 W

Battery: external manufacturer

Torque: 90 Nm

Motor already used by: not available until 2020/21

More infos at: poliniebike.com

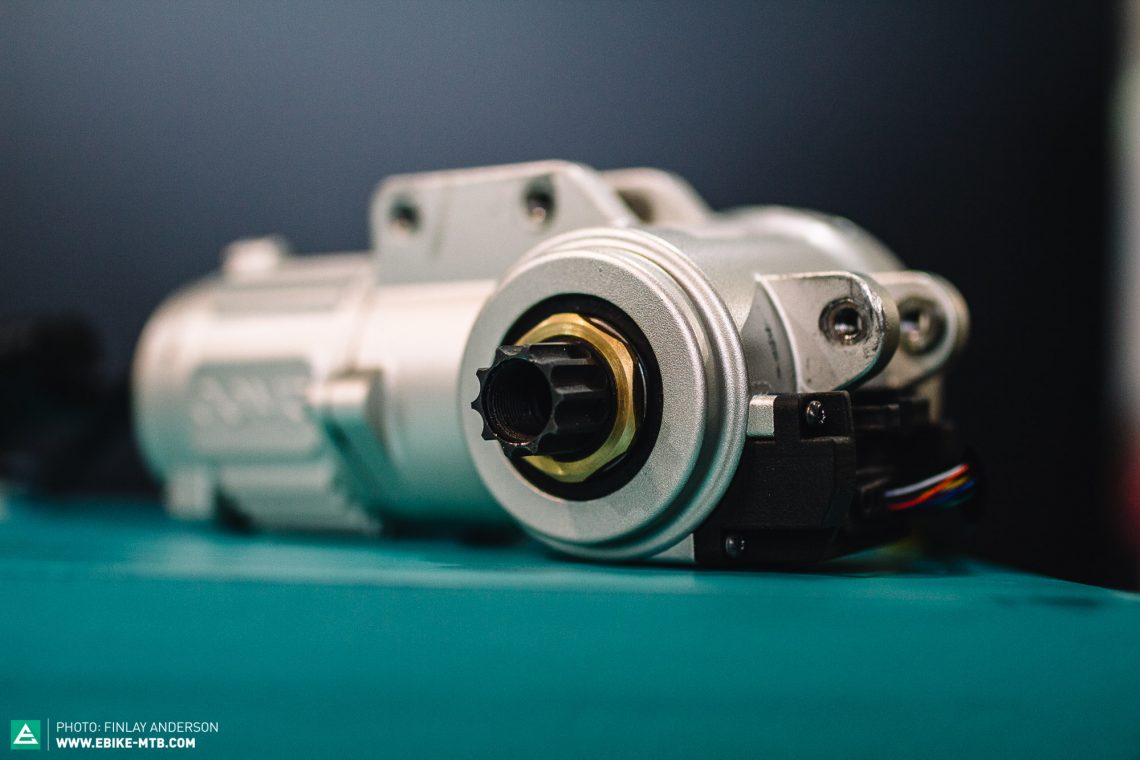

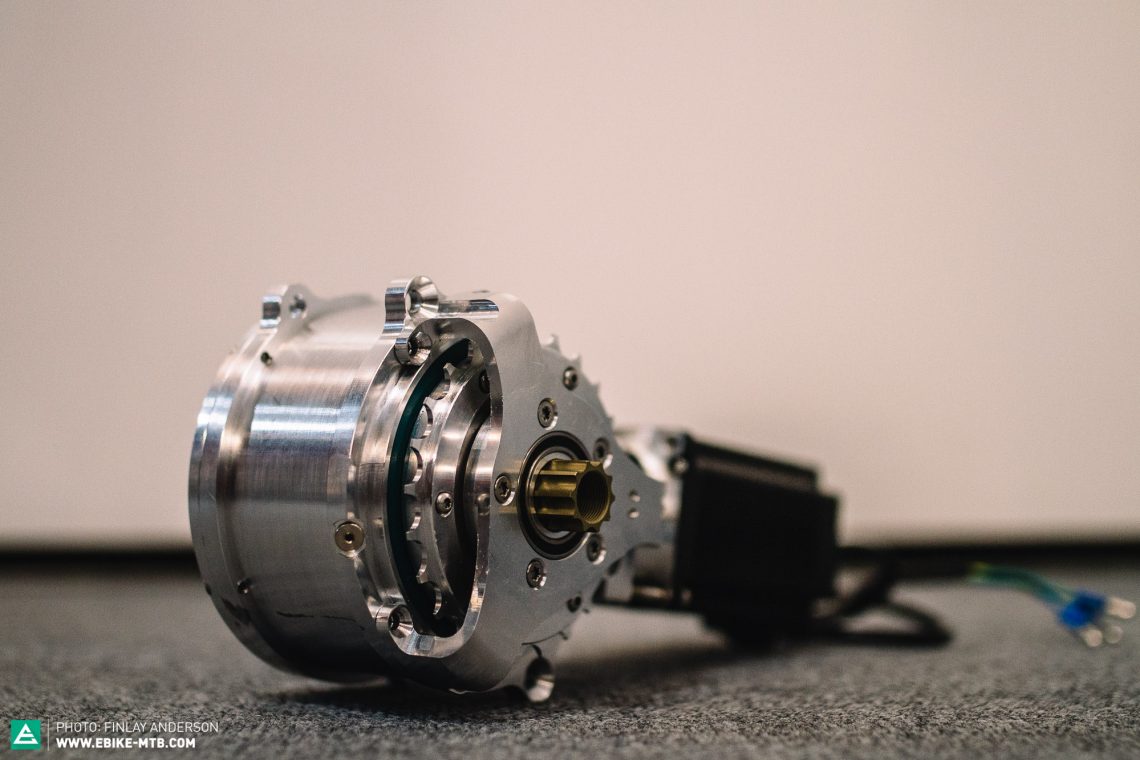

Revonte ONE

By using a Continuously Variable Transmission (CVT) on its drive system, the Finnish startup eliminates the need for a conventional groupset. Whilst the system with a single-speed setup is not the only one on the market, it relies on a robust CVT hardware, which has already proven itself in the automotive industry. The system is smaller than most other similar concepts. The Finnish manufacturer, which employs some of Nokia’s former workers, wants to achieve a smooth ride through a consistent cadence. As with the automatic car-transmission, the software controls the gear shifts. Manual gear changes can also be implemented using the software. In addition to all the current standard functions, the dedicated smartphone app includes anti-theft protection and direct motor adjustments. Bike manufacturers can decide whether they want to use a belt or chain drive –the low maintenance system is designed for both!

Whilst the strengths of the brand lie in the software, their vision involves an open software system (Linux), which allows bike manufacturers and end customers to freely customize the motor and adapt it to their needs. Revonte also provides the batteries and shifters, with the end customer’s smartphone serving as the display. The software is currently being optimized on a test bike. The first eBike manufacturers will be able to test the system from mid-October. Mass production is scheduled to start in the second quarter of 2020.

Dimensions: 112 x 120 x 200 mm

Weight: 4.7 kg

Nominal power: 250 W

Bandwidth: 416 %

Battery: 635 Wh

Torque: 90 Nm

Motor already used by: test bike

More infos at: revonte.com

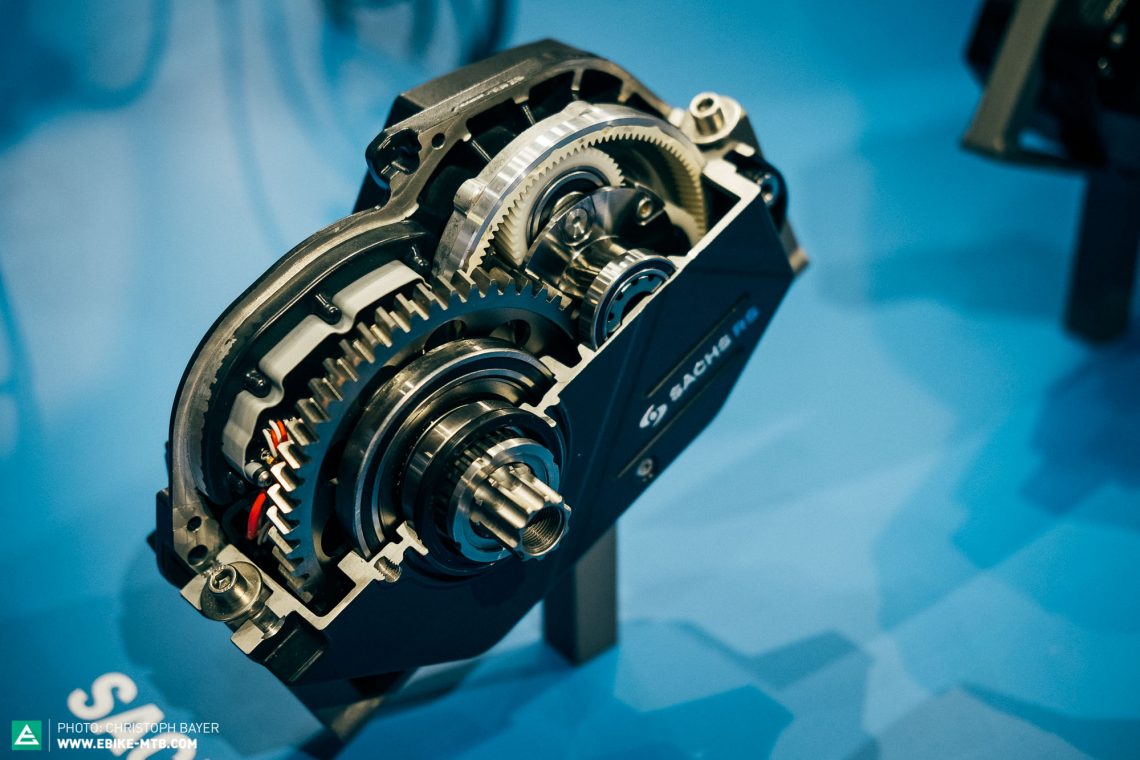

Sachs Micro Mobility: a motor platform for eMTBs, sPedelecs and cargo bikes

Sachs have developed a new platform which thy use on three different motor models. We have already tested the Sachs RS 925 eMTB motor, but a lot has happened since, especially in terms of software tuning. The 48 V system provides up to 380% support. The high torque should be of great help especially on startup, because the RS 925 is meant to push strong from a low cadence

The Sachs RS 845 is the sPedelec version of the motor, which supports the rider up to a speed of 45 km/h. Whilst the motor offers a support of up to 420%, its housing has been adapted to ensure better cooling. The Cargo version CT 725 also offers 420% support but is tuned differently to provide maximum torque right from startup.

Dimensions: n/a

Weight: 3.5 kg

Nominal power: 250 W

Battery: 650 Wh

Torque: 112 Nm

Motor already used by: –

More infos at: zfmicromobility.com

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of E-MOUNTAINBIKE, you will help secure a sustainable future for high-quality cycling journalism. Click here to learn more.

Words: Manne Schmitt, Felix Stix, Christoph Bayer, Jonas Müssig Photos: Finlay Anderson, Manne Schmitt, Felix Stix, Christoph Bayer, Jonas Müssig