Is innovation always better? Or is a good made evolution better than taking the risk of a revolution? We visited Canyon Bicycles in Koblenz and talked to the development team behind the new Spectral:ON CF about its creation and the challenges they face as a direct to consumer brand.

Full exhibition halls, crowded aisles and new, perfectly staged bikes everywhere. EUROBIKE 2014 is in full swing and one of the biggest highlights of the fair is the connected bike at the Canyon booth. Together with Telekom Germany, Canyon presented a road bike with an integrated SIM card, automatic crash detection, a tracking function and a host of other super innovative features. Canyon are able to recognise trends and implement innovations like no other, but the Connected Bike or even basic features of it haven’t yet made it to market. And there is a reason why, as the director of the e-performance department, Philipp Klein, and product manager, Sebastian Opalla, engineer, Patrick Schmidt, and designer, Christian Parmenter, explained to us when we visited them in Koblenz. The four employees working in the e-performance department also revealed the most unique features, highlights and challenges in developing the latest Canyon Spectral:ON.

Direct to consumer – Canyon’s sales model

By now, every rider knows that Canyon deliver their bikes directly to their customers, thereby cutting out the bike dealer as a middleman, allowing them to offer first-class value for money regarding componentry and tech. However, what few people know is that this sales model also has a major impact on the development, assembly and components of their bikes. Besides the performance of their bikes, the complete experience along with the product and, of course, customer service also plays a decisive role in customer satisfaction.

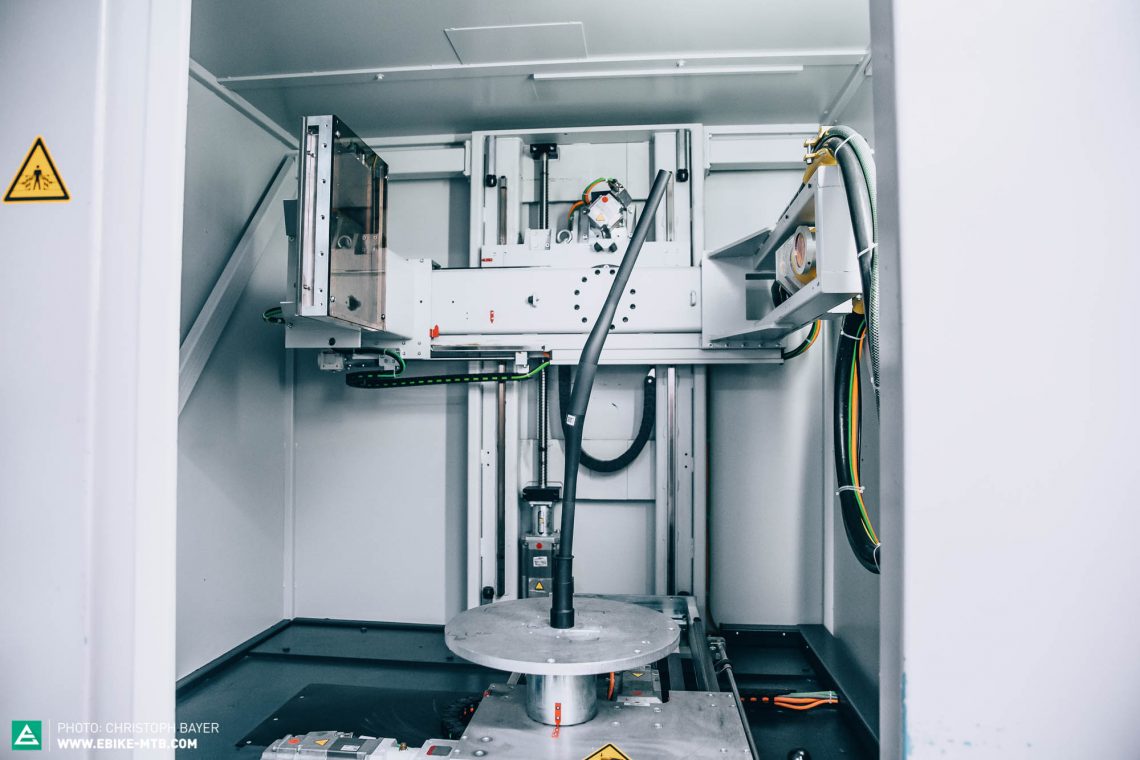

While a classic bike brand always has to rely on the local dealer as a middleman, who can assemble the bike and deal with minor problems and address customer concerns directly, at Canyon the customer has to deal with the manufacturer themselves. Here, if the drivetrain doesn’t work properly or if you’ve got a problem with defective bearings, you’ll have to write an e-mail or pick up the phone. This doesn’t only harm the brand’s image and thus the sale of new bikes, it also costs money. After all, the more customer complaints you have the more customer service representatives you have to employ. So, the last thing Canyon want is dissatisfied customers. For this reason, all new bikes are assembled, checked and adjusted by qualified bicycle mechanics before they’re sent off to the customer. Using for example a smart torque wrench, all bolts are tightened at the correct torque and the torque setting are saved in a digital record. Every in-house carbon handlebar gets quality-checked by a CT scanner – it’s a lot of additional work, but Canyon tell us they’re happy to do it, not least of all to guarantee customer safety.

During our visit, the team openly admitted that they haven’t always been able to deliver the service that they wanted to in the past, as with the IT problems they encountered in 2015. According to their own statements, all processes are now running smoothly as planned and the bikes are pre assembled and delivered to their customers on time.

Packing a bike into a box isn’t that easy with an eMTB

Every Canyon eMTB gets delivered in a special E-Bikeguard box. It’s quick and easy to remove and ready to ride in just a few steps. The last thing you want as a customer is to have to put the bike back into the box. Since defects can never be completely ruled out, Canyon haven’t only started to cooperate more with local bike shops, but they’ve also deliberately chosen not to develop their own battery or combine the motor with the battery of a third-party provider when developing the new Spectral:ON. Instead, the direct to consumer brand relies on the complete Shimano system. In the event of a defect, you know exactly who to go to, and the manufacturer also has a huge network of qualified service centres to rely on. If you encounter a problem with the motor, you should be able to fall back on one of these service centres. In this sense, factors such as the service network and the availability of spare parts are just as important to Philipp’s decision as the motor’s mechanical specs.

Democratised performance – best performance at the fairest price

Achieving the best performance on the trail at the fairest price – this has been Canyon’s goal since the company was founded. However, that doesn’t mean building bikes as cheap as possible. During development, Canyon always strive to find the right balance in their effort to create the best bike for a specific purpose while also avoiding unnecessary expenses. As all of their bikes, the new Spectral:ON was developed with this mindset. It’s an eMTB designed for demanding trail riders and, unlike its predecessor, features a carbon frame. Compared to the previous model, Canyon themselves speak of an evolution instead of a fundamental revolution. The geometry has been tweaked to improve the bike’s climbing capabilities, and the suspension kinematics have been optimised so that the travel can be used even more effectively. For all the details and how the bike rides, check out our first ride review of the new Spectral:ON CF.

It’s all in the details

Small details can often make all the difference. An excellent example of this is the specially developed saddle that Canyon presented on the first generation Spectral:ON. With its raised rear end, it offers plenty of support on steep climbs and thereby significantly improves the bike’s climbing characteristics. With the new Spectral:ON, Canyon have now gone one step further. Though they rely on a complete third-party system for the motor, this hasn’t stopped them from tailoring the bike to suit its intended use. As Christian explained to us, it all starts with a coherent frame design with all of its proportions adapted to the larger volume tubes required for of an eMTB with an integrated battery, and it continues with the details. Canyon developed a total of 21 components in-house, specifically for the new Spectral:ON. The new bike comes with a one-piece handlebar and stem combination, featuring an integrated display mount and internal cable routing. The battery cover is matched to the colour of the frame and the grips have a narrower clamp to give your hands more space with all of those levers on the handlebar. They even designed an Allen key to hang on your keychain with which you can remove the battery. We could go on: there’s the chainring developed in-house, as well as the chain guide and the integrated USB-C socket to charge your smartphone directly via the bike’s integrated battery.

Our visit to Koblenz proved how much complexity is involved in achieving the optimal balance between performance, value, reliability and customer service and that the quality of a bike can’t be seen from glancing at its spec sheet. What good is the best-specced bike if it ultimately spends more time in the workshop than on the trail? Canyon claims to have mastered this balance with the new Spectral:ON and Shimano’s proven ebike system – whether they’ve really achieved what they set out to do, you can read on our first ride review.

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of E-MOUNTAINBIKE, you will help secure a sustainable future for high-quality cycling journalism. Click here to learn more.

Words & Photos: