How do you turn electricity into an enjoyable bike ride? In other words, how do you develop an ebike motor system? We met with Bosch eBike Systems to discuss the most interesting aspects with their developers, product managers and the CEO Claus Fleischer, and to give you a look behind the scenes at the ebike behemoth. Enjoy the ABC of e-motor development!

Failures and successes: The market for ebike motors has many players and is still growing. However, lots of players have also left the field along the way, with failures and bankruptcies common. And then there is Bosch eBike Systems: the developer of drive systems are not only pioneers in the field of ebikes, they have also played a key role in shaping the market since its very beginnings and have consistently expanded their market position.The Bosch eBike Systems success story also features the fact that the Swabians are voted BEST BRAND in the motors category by our readers, year after year.

If you’re curious about the factors that contributed to Bosch’s success, you’ll find some clues in Robert Bosch’s memoirs. More than a century later, his memoirs still serve as a guideline for the entire Bosch Group. On the subject of competition, the company founder wrote: “In my experience, there is nothing worse for a company that wants to survive and progress in the long term than not having a competitor.” One hundred years after he wrote his memoirs, Robert Bosch’s wisdom still holds true. But there is surely more to success than just competition stimulating the business. To unravel the recipe for success, we ventured to the headquarters of Bosch eBike Systems in Reutlingen, Germany, to get some insights into the behind-the-scenes world of e-motor development.

The ABC of electric motor development

Right from the start, our flying visit to the Bosch eCampus differs from most of our previous field visits. A brief welcome at the reception desk is followed by a bureaucratic process of checking IDs, asking about access rights and obtaining permission to take photographs. The programme includes not only a tour of the trophy cabinet and the wall of exhibits, which vividly depict the company’s history, but also a glimpse of what lies behind the security gates at Bosch. However, we are not granted unrestricted access; we are allowed to visit the development laboratory, the system test bench, the test tracks and a conference room.

As mentioned at the beginning, the ebike industry now boasts an incredible number of motor manufacturers and brands. However, despite the seemingly low barriers to entry, a number of factors play a key role in determining success or failure. While we’re at Bosch, we want to explore possible approaches to successful motor development. At first glance, the new Performance Line SX motor may not appear to be the most innovative, compact or light motor in its category, but it offers many advantages. Some are specific to this motor, such as the balance between minimal assistance and full power, while others are more characteristic of Bosch. So what’s it all about? What is the ABC of motor development? If anyone can make more out of E than just the fifth letter of the alphabet, it’s Bosch.

A as in Analogue bike

If you want to develop an ebike motor, you have to start with something we all love: the analogue bike. Many of us discovered our love for biking on analogue bikes, without electric assistance. That’s why you first have to ask and answer a few basic questions to understand the needs and expectations of the riders. What does an analogue bike offer us and what do we love about it? What can a motor system improve, which individual needs are better met with an electric tailwind, and what should never be compromised by a motor?

In addition to former analogue bikers, there are many other target groups who have only discovered that two-wheeled travel is one of the best ways to explore the world or to get around in everyday life thanks to the electric motor. To get these new riders on board, we need to step away from the analogue bike and ask different questions. What does the e-drive allow that would not have been possible with a purely analogue bike? What are the new requirements, skills and needs of this audience?

As we look at the exhibits from the company’s history with CEO Claus Fleischer, the evolution from analogue bike to ebike becomes obvious. The first prototype, built in 2009, started out as an off-the-shelf analogue bike, which was later transformed into an “analogue bike with an electric motor” through the addition of generous amounts of gaffer tape, cable ties and some extensive tinkering. It is miles away from what we think of as a modern ebike today. Over time, motor system developers and bike manufacturers have understood that an ebike is more than just an electric motor and battery bolted to an analogue bike, and that the needs of different audiences go far beyond hardware. It started with issues like performance and quality, then visual and technical integration into the bike for better design and handling. At some point, the great battery race began, with an irrational, obsessive demand for ever greater battery capacity. This, of course, came at the expense of handling, integration and weight. As a counter-trend, the supply and interest in light eMTBs increased. And the evolution continues: connectivity, usability, digital services and customisation are the buzzwords of the moment.

But that is not all. Some manufacturers, led by Bosch, now offer everything from urban bikes and cargo bikes to all kinds of trekking and SUV uses, adventure bikes and powerful race eMTBs for chasing seconds at international events. The latest creation is the Bosch Performance Line SX motor, which is the closest thing in the company’s portfolio to an analogue bike feel, and is expected to once again pave the way for new bike innovations.

B as in Battery

Next in the alphabet is B for battery. As soon as you learn a little more about the subject, you’ll know: battery ≠ battery. And again, it is much more than just the nominal capacity of the battery that counts. Dimensions, electrical power, clever heat management and, of course, cell chemistry are crucial. We delve into the technical details with battery expert Dr. Vikram Godbole, Senior Product Manager Batteries & Chargers at Bosch. We quickly realise that we’re a bit out of our depth – Vikram really knows his stuff: after all, he has been working on batteries at Bosch eBike Systems for the past 10 years, having previously worked as an R&D scientist in the field and wrote his dissertation on lithium-ion batteries. For Bosch, motors and batteries should be developed in harmony. Yet Bosch’s approach is the exception rather than the rule in the ebike industry. Competitors such as Shimano and Brose also offer their own batteries for their motor systems. However, they leave it up to the bike manufacturers to decide which batteries to use, and also allow the use of third party batteries. This offers pros and cons: on the one hand, wider choice and greater flexibility, but also less control and more fragmented motor systems. Bosch like to develop the batteries themselves, starting at the most elementary level: cell chemistry. To achieve the optimum power and energy density for an ebike battery, cells are not just bought off the shelf, but are developed to Bosch specifications. The development leaps in the early years were particularly impressive: for example, a higher proportion of nickel greatly increased the energy density. The first ebike battery from Bosch had an energy content of 288 Wh and was rather bulky. Today, the PowerMore Range Extender has almost the same capacity at 250 Wh, and the battery itself is no bigger than a drinking bottle.

Of course, the positive development in energy density has not been the exclusive preserve of Bosch; the other manufacturers have also been able to present ever lighter, smaller and more powerful batteries. However, according to Bosch experts, current lithium-ion technology will soon reach its limits, and new battery technologies will have to be developed. With small and lightweight batteries, heat generation and thermal stability can become a bottleneck to the performance of the electric motor system, and the same applies to the motors. Especially in the motor systems of light ebikes, a relatively high load is distributed over smaller and lighter components in the motor and over fewer cells in the battery. As a result, thermal management is a key issue and needs to be handled by an intelligent battery management system. When the motor and battery come from the same manufacturer and their power ratings are precisely matched, as is the case with Bosch, you can imagine the current performance benchmark that is achievable: the small Bosch Performance Line SX motor achieves a peak power of up to 600 watts despite a motor weight of approximately 2 kg and a relatively small 400 Wh battery, which puts it more in the league of heavier full power motors.

Vikram is not only an expert on batteries, but also a product manager for chargers and batteries, and he anticipates another point on our tour of the eCampus: B for building block or modular system. Battery sizing not only affects technical parameters such as motor performance, range, longevity and charging speed. It also affects the overall concept and design of the bike. Size, weight and shape determine how well the battery can be integrated into the ebike and thus the centre of gravity, the layout of the frame and as such the rear suspension kinematics, and ultimately the overall handling. While the first generation of Bosch ebike batteries was very restrictive in terms of design, Bosch’s third generation motor system, the Smart System, offers a variety of battery shapes, which are also cross-compatible with all Smart System motors. For example, there are still external batteries, such as the PowerPack Frame, that can be removed quickly and easily. This is particularly useful for urban ebikers, who can’t always store their bikes near a power outlet so need to take their batteries with them. It also enables concepts such as the race-oriented Lapierre Overvolt GLP III, which has a particularly well-balanced, central centre of gravity and allows the battery to be changed in seconds under the pressure of race conditions. The internal CompactTube and PowerTube batteries, which can be installed in the frame, have battery capacities of 400–750 Wh, providing sufficient energy reserves for most rides: from a short after-work ride to a long day tour. To meet the needs of cargo bikers and long-distance explorers, Bosch is working on the DualBattery system for the Smart System, which is due to be launched in 2024. This will directly double the battery capacity. However, any motor/battery combination from the Smart System can already be paired with the PowerMore range extender with 250 Wh to flexibly squeeze a little more range out of the system. And even for city bike manufacturers who don’t provide a special mounting point for the battery on the frame, Bosch have a solution with the PowerPack Rack: a battery that simply sits on the luggage carrier at the rear.

When asked what is still missing in the Bosch battery cosmos, the answer is “a standardised plug”. This is at the top of the wish list not only of ebikers, but also of manufacturers. The idea is to be able to use a single charger for all ebikes and, if possible, not have to rely on your own brand- and motor system-specific charger on tour. Instead, you use a charging infrastructure with a plug that is compatible with any ebike, for example in cafés in cycling regions, or in mountain huts on an Alpine crossing. This is why Bosch eBike Systems is engaged in the CHAdeMO consortium, which is already driving forward the standardisation of the charging infrastructure in the electric car market.

Sebastian and Simeon join us in our discussion about the modular principle. Before they take us to the letter C, they would like to add Bosch service quality to the letter B. Because the proper ABC of e-motor development includes not only all the hardware spread out on the table in front of us, but also a comprehensive service network that keeps all Bosch ebikes around the globe running. In addition to a guaranteed supply of spare parts, this also includes comprehensive dealer training. One reason why Bosch always comes out on top in the popularity stakes of our annual reader survey is that it is easy to find a local contact. To ensure this, Bosch eBike Systems runs an extensive dealer training programme, with over 17,000 training participants expected in Europe alone this year. In addition, there are 350 shops in Europe that have been certified as Bosch eBike Experts and receive ongoing training. Special tools and software are also being developed for dealers, such as the CapacityTester, which allows the local bike shop to diagnose battery faults, for which other manufacturers require the battery or the entire ebike to be sent in. At the moment, there are very few e-motor manufacturers that have developed a good regional presence, let alone the mammoth task of a global service network.

C as in Control

For the letter C, we have to go through several stations on the Bosch eCampus, explain Sebastian and Simeon. They are actually quite far down the process chain and apply the motor system software to the hardware. In a narrow sense, C stands for control; in a broader sense, it includes communication, configuration, customisation and collaboration. What does that mean? At its best, a good ebike motor knows what the rider is doing. It recognises the riding situation and adjusts its motor power accordingly. At the same time, the motor must react in a predictable and appropriate way so that the rider is not subjected to unwanted surprises. In the first generation of Bosch ebike systems, there were only two arrow buttons to switch between the linear riding modes of Eco and Speed. Everything else had to be controlled by your own input on the pedal. That worked in the days when we rarely rode in technical terrain. But the way we ride eMTBs has evolved. Dynamically changing riding situations leave little time for awkward communication between man and machine.

Since then, Bosch have made great strides in motor tuning and configurability and are one of the leaders in the ebike industry. There isn’t only a wide range of motors, but also a wide range of tuning options that can be loaded onto the ebike depending on the intended use. For touring bikers, for example, the dynamic Tour+ mode continuously adjusts motor power to the environmental conditions and riding style. On the flat, it is designed to provide gentle, battery-saving support to achieve a high range. When you start to climb or get into a strong headwind, the motor senses the increase in rider power and adjusts its own power output accordingly, giving you a smooth riding experience without having to constantly press buttons. The counterpart for sporty riders is the eMTB mode, which regulates motor power over a wide range and is adapted to technical riding manoeuvres such as starting uphill or tackling steps. This allows riders to intuitively control motor power, even in tricky situations where there is no time for pressing lengthy button combinations on the remote. Another example is the Race mode, which has been specially developed for racing and is used exclusively on the Bosch Performance Line CX Race motor. It’s characterised by a particularly direct response combined with brute power delivery, so that professionals with a high level of bike control don’t lose valuable seconds on the trail. Bosch are also applying the experience they have gained in the field of precision motor sensors to other products, thinking beyond the limits of pure motor systems. With the second generation of Bosch’s eBike ABS, for example, the company have a trail-ready anti-lock braking system in their range that gives both ebike newbies and experienced riders more control over their front wheel in critical situations, and thus greater safety.

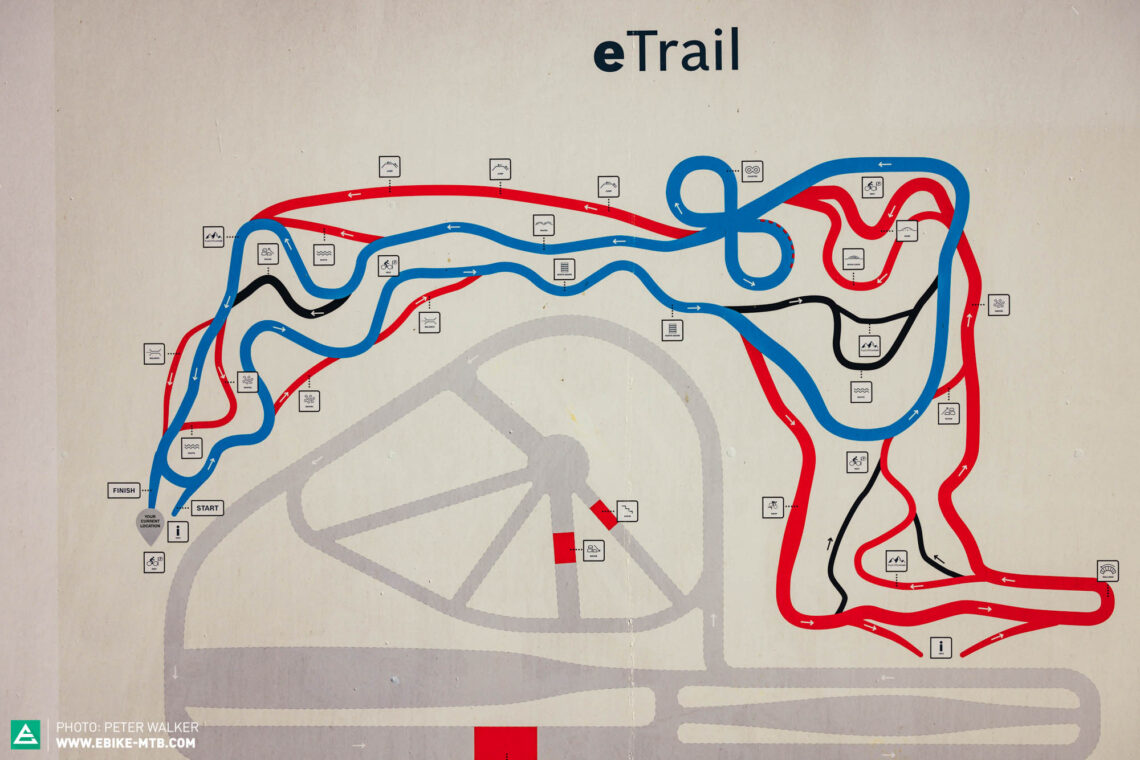

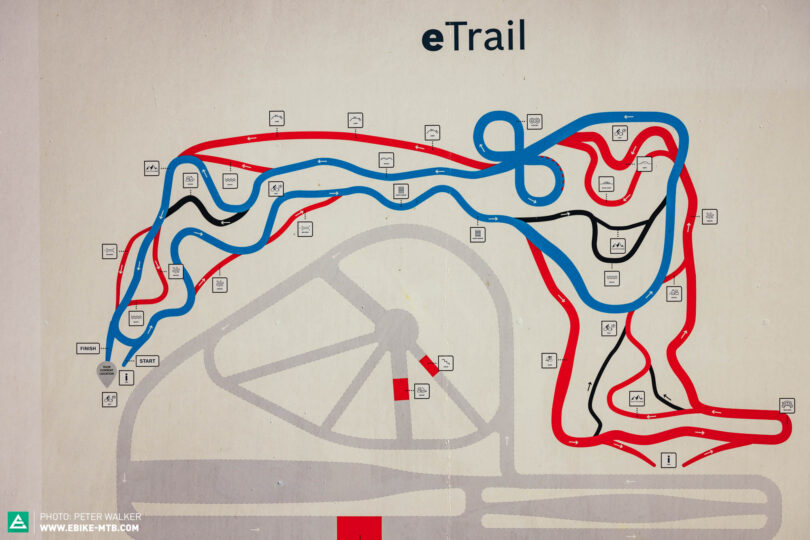

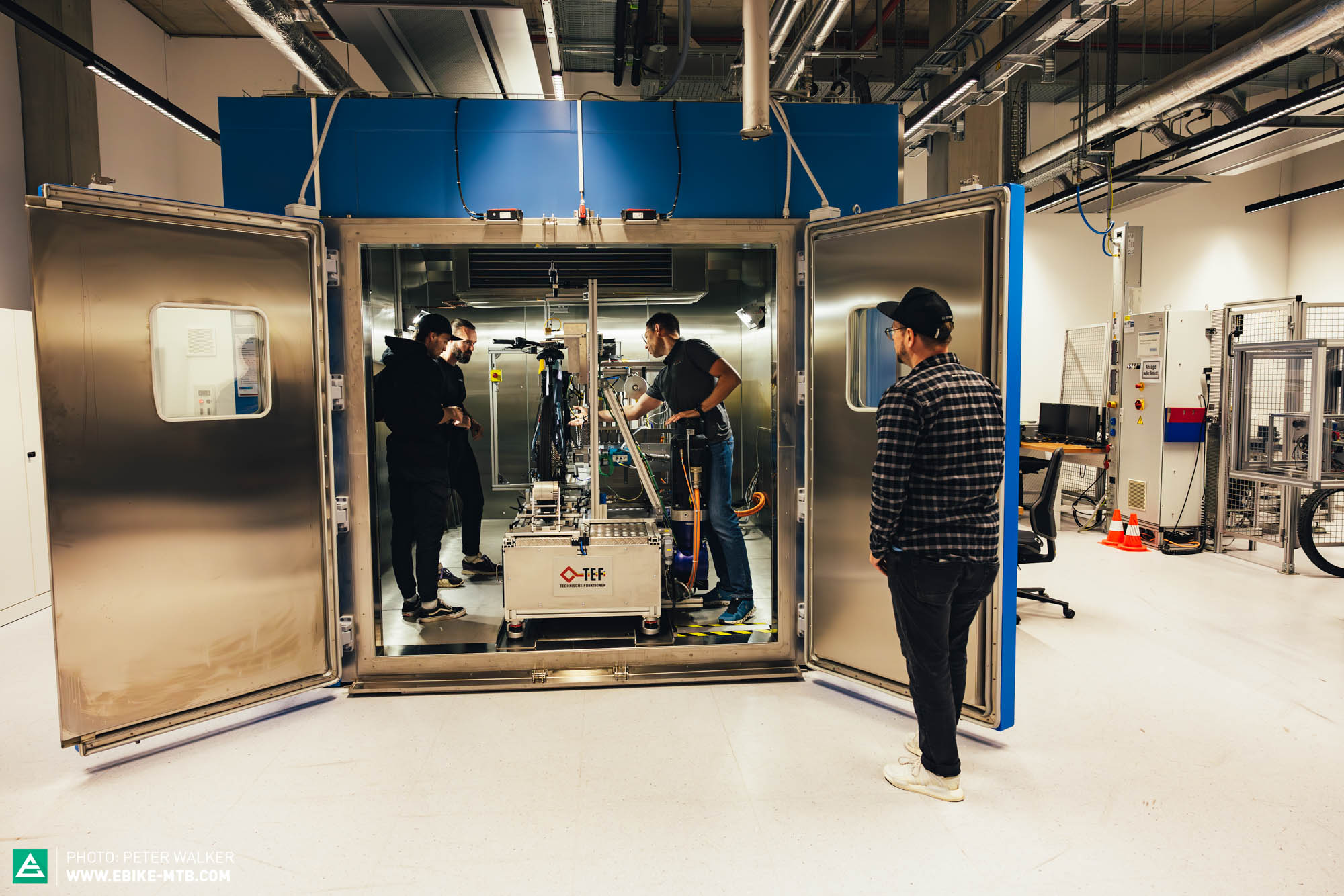

Despite the already fine-tuned motor characteristics, Bosch leave the final touches to the rider. Each mode can be further adjusted via the eBike Flow app to suit individual needs in terms of power and dynamics. The basic motor tuning process requires five locations, only three of which are on the eCampus. The software programmed in the development offices can first be validated in the in-house system test bench. Without revealing too many technical secrets, we can only say that the Bosch system test bench is state of the art. It has a particularly high level of dynamic control to simulate racing situations and can measure power and performance at several different points on the bike. This allows conclusions to be drawn regarding the precision and performance of the software and hardware, as well as quality control. Which brings us back to the C of Control. The system test bench allows continuous operation from morning to evening and doesn’t complain about overtime if the 40-hour week has already been reached by Thursday noon. But as good as the test facility is, it cannot replicate the human factor. That’s why we’re leaving the building complex on the campus for the first time and heading to the in-house test track.

The Bosch employees need a permit to use the test track. And we need a liability disclaimer. Various obstacles, climbs, trail conditions and curve radii, including elaborate wooden structures, have been built on the test track. The test track is very “nice”, but it doesn’t offer the opportunity to test the most important of all riding characteristics: Fun! For that, we would have to leave the campus and explore the surrounding trails, but with 23 more letters in the alphabet, there is no time to spare. The developers also maintain close relationships with professionals from various ebike racing series. This way, feedback from riders at the highest level also flows into their development.

There is another C in the ABC of electric motor development that Bosch take into account, but which is overlooked by many competitors: C for cooperation and collaboration. It goes without saying that bike manufacturers work together with Bosch and communicate their requirements and wishes. That’s why, according to Bosch, more than 100 well-known manufacturers have opted for a Bosch motor system. Collaboration, however, means something different, which for Bosch eBike Systems is tantamount to a trend reversal. They want to give the manufacturers more influence and take a back seat. As a biker, you will notice this in subtle changes, such as when you open the eBike Flow app and are greeted by a Trek or Cannondale logo instead of a Bosch start screen. Up to now, Bosch have been more dominant in this area. Customers’ loyalty to the bike brand was based on the Bosch motor. In our reader survey, more than 40% of all participants said they were riding an ebike with a Bosch motor and would like to have one on their next ebike. With a more discreet appearance, Bosch want to promote the brand awareness of the manufacturers, which is beneficial for the customers’ loyalty to the bike brand – after all, there is more to the way an ebike rides than just the motor. That makes the manufacturers particularly happy, of course. The question of how Bosch came to change their mind brings us back to our first respondent, Claus Fleischer.

C as in CEO, or Claus Fleischer

Claus has been Managing Director of Bosch eBike Systems since July 2012, in other words he has been with the company almost from the beginning. Talking to him, it quickly becomes clear that he doesn’t fit the classic image of a CEO of a large corporation with only an eye for sales and profit figures. A passionate rider himself, he spends almost every free minute on his bike. Not only does he know the Bosch ebike portfolio inside out, he also has a feel for the needs of the bike community and a real soft spot for the ebike racing scene. Of course, the success of a company can never be attributed to just one person, it always needs a strong team – as the company’s founder Robert Bosch already knew. However, Claus sits at the intersection of the corporate world and the bike world, which sometimes have different views that need to be balanced and reconciled. The process-driven side of the company, the high level of professionalism that goes with it and the rigid process-oriented structures are noticeable at every security gate and checkpoint. If you want to produce quality in series, you need this process-driven approach. But it often causes friction in the more laid-back bike industry. Claus combines both worlds and, together with Stefan Schlie, has successfully turned his own personal passion, Uphill Flow, into a company project: riding fun that not only thrills on the flat and downhill, but also uphill. Not only did they develop the matching motor system, they are also involved in various initiatives, including trail construction to ensure trails that offer riding fun in all directions. He is also highly engaged and actively lobbies at both community and industry levels, whether it’s for ebike and trail legalisation or e-racing sponsorship. Whatever the subject, Claus is someone you can talk to on an equal footing, and who shares the same values as most bikers. But before we get too carried away, Roumen, the product expert for digitalisation and marketing, takes us to the next letter.

D as in Digital Environment

Roumen’s field of expertise is not so easily associated with a physical location, but rather takes place in a virtual space. We are talking about D for digital environment. The first Bosch ebikes were created in the midst of the digital age. However, the opportunities offered by technology and digital tools were somewhat neglected. Connectivity was seen as an add-on rather than part of the product experience. Today we know that it is no longer just about cycling and that the focus is increasingly shifting from hardware to software. For Roumen, it is clear that when you buy a bike with a Bosch Smart System today, you are not only buying the hardware, but also the software with all future updates and a comprehensive service package. The digital environment is increasingly becoming part of the business model, as you can subscribe to additional digital services.

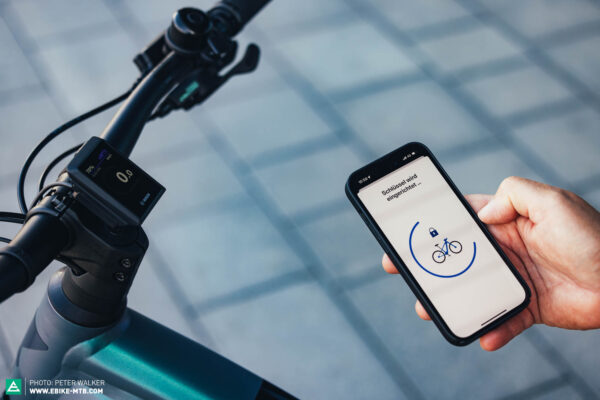

Bosch’s previous digital ebike environment was a private club with a strict doorman. Bosch want to loosen the strict access control and enable more connectivity points for cycling-related services. Well-known fitness and activity tracking providers such as Strava, Komoot or Apple Health will find their way onto the ebike, and other, smaller service providers will follow in time. In addition, a strong digital environment helps to approach the development of motor systems from a user experience perspective. This means, for example, that all motors in the Smart System can be updated over-the-air. Not only will this make life easier for dealers, but it will also enable riders with Bosch motors to keep their bikes up to date and add new features. Many bikers were probably amazed when, after the update in November 2022, the eBike Flow app combined with the KIOX 300 display suddenly had a navigation function.

Another way to enhance the customer experience is a premium service package from a single source. For the Smart System, this means the link to the Bosch ConnectModule. The tracking module, which is concealed within the bike, offers theft detection and alarm functions. This could also form the basis for insurance cover with a replacement option. With the Flow+ subscription service, Bosch already have their own theft protection in the programme, which not only acts as a deterrent but also provides a sense of security.

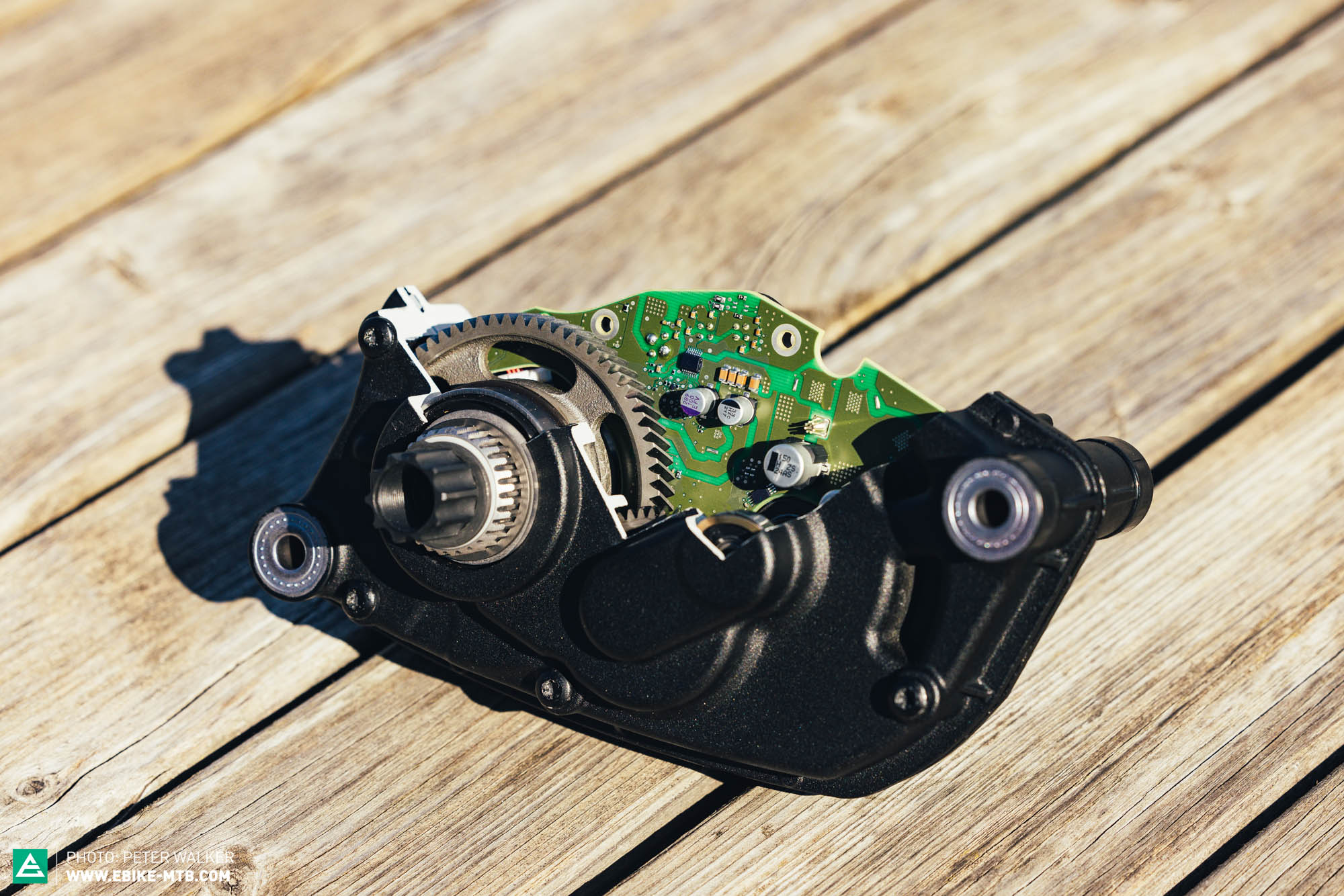

E as in Electric Motors

You run a few volts and amps through a handful of wire coils, which generate a magnetic field that interacts with the magnetic field of a permanent magnet. Woosh, you’ve created a rotary motion and the ebike motor is ready – or is it? Well, not quite. After our odyssey through the eCampus, it’s pretty clear: to successfully develop an e-motor, all the knowledge gathered from A to D must be carefully examined and integrated into the motor system. Of course, the size of the motor, its weight, the materials used and the laws of physics themselves all impose limits. You can explore these limits to the full or even try to circumvent them in order to develop ever smaller, lighter, stronger and more robust motors. But this is not the recipe for success. The motor hardware is just the base, the motor system gives the character, the software brings the system to life and the service around the ebike guarantees satisfaction for the long run.

If you were to revisit the initial question “What do we love about analogue bikes?” from the perspective of an athletic mountain biker, the following things would be at the top of the list: a sleek, minimalist look; light and nimble handling that provides a natural riding experience; and the direct connection between the rider’s own power and the bike’s propulsion. If you were to design a suitable electric motor and motor system for this type of rider that wouldn’t interfere too much with the look and feel of an analogue bike, you would probably end up with a minimal assist motor. Does it have to be the new Bosch Performance Line SX Smart System? No, there are plenty of other fish in the sea that may be lighter, more compact and easier to integrate. But there are many reasons to choose Bosch, with its holistic approach in quality. And, of course, the fact that the motor, with its peak power of 600 watts, closes the gap between minimal assist and full power motors, making some new and exciting bike concepts possible.

The road to success has been mapped out, and no matter which manufacturer you ask today, Bosch get a lot of things right. This can be attributed to E: Bosch’s many years of experience, another key success factor in the ABC of electric motor development. In 2019, Bosch eBike Systems celebrated their 10th anniversary. In human years, the company hadn’t even reached their teenage years, but in ebike years they were already a veteran in the industry. In 2021, the Smart System was presented, the third generation of the motor system after just 12 years of company history. This shows how fast the ebike market is developing and how much pressure there is to innovate. The way we ride and what an ebike is used for is still evolving. Bike and motor manufacturers also need to evolve, as does the bike community. There is still too much irrational willingness to buy the bike with the highest torque or the biggest battery instead of looking at the whole concept. The Bosch SX motor is a step towards the diversification the market desperately needs. The more diverse the market, the more new applications can be developed, allowing ebikes to evolve in line with our changing riding habits.

E also stands for the end. The End?! Wait, aren’t there 21 letters missing? Well, after a long day at the Bosch eCampus, we came to the conclusion that successful e-motor development is too complex to be captured in the 26 letters at our disposal. The only letter we’d like to add is F for fun, and we’ll finish with this: if you’re having fun riding, the rest of the alphabet doesn’t matter.

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of E-MOUNTAINBIKE, you will help secure a sustainable future for high-quality cycling journalism. Click here to learn more.

Words: Rudolf Fischer Photos: Peter Walker