TQ – a cryptic acronym that stands for something downright simple: Technology in Quality. The Bavarian brand has already sent their eponymous principle into space (quite literally), and are now pursuing the ambition to become a major player on the e-bike scene. Having paid a visit to TQ, we can testify that there’s a whole lot more to this brand than just their powerful motor.

Up until now, most e-mountain bikers may only have heard the name TQ in passing. Their incredibly powerful motor has spread the name TQ in certain circles, but most riders won’t yet have had the opportunity to try it out. Having created such a stir, we wondered what exactly is behind TQ and where did they get such know-how? For those who are expecting your standard motor manufacturing company, think again. TQ has a far broader focus on technology, including electronic control systems for passenger planes and components for medical robots. If you needed any more convincing, the Bavarian company’s motors are often sent into space. If that isn’t high flying, we don’t know what is. The company is broadly positioned and now aim to channel their extensive knowledge into the eMTB sector. The most recent piece of evidence is the all-new Haibike FLYON bike, which utilizes a legion of TQ technology.

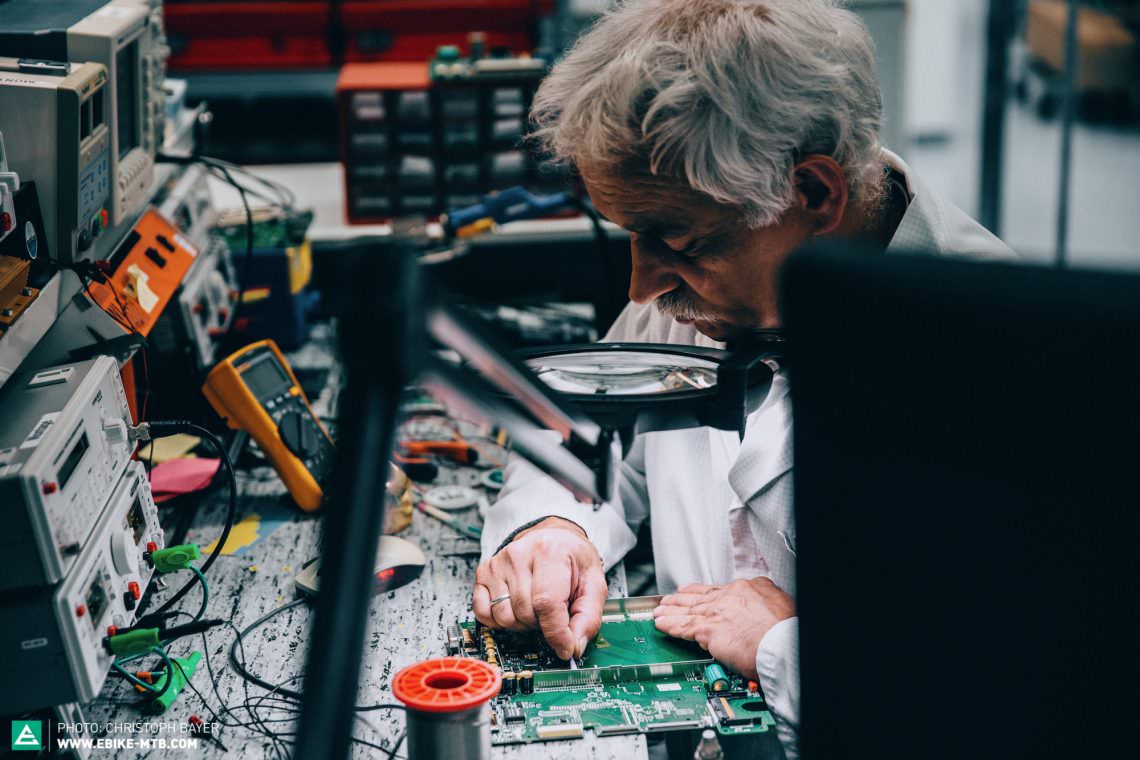

But how did TQ even get this far into the world of e-bikes? The TQ Group’s story first began in 1994, when Detlef Schneider and Rüdiger Stahl set out making circuit boards in a small room in postcard-perfect Upper Bavaria’s Gut Delling. Circuit boards are those green things in every computer; that thing that most humans wouldn’t even know its top from its bottom. TQ still make these today, although there are now 1,600 members of staff (not just two), and they’re spread across 13 locations. Both of the founders are still active in managerial roles now, with Detlef Schneider’s son Stefan working alongside them.

One of the TQ’s biggest strengths has always been their ability to recognise potential – really early on, whether this applies to acquiring new locations or breaking into new lines of business. Back in 2008, they essentially ‘fell into’ the e-bike world with the chance development of their own e-bike motor. Back then, they had a part-time developer on their books – a certain Toni Rossberger, who is a motocross stuntman and appeared regularly on national television with stunts including daredevil ski jumping on his bike. Toni was contacted by the start-up Clean Mobile, who wanted his assistance in creating a powerful drive unit for e-bikes. TQ were keen, firstly sharing their development know-how and then injecting the necessary capital when the start-up went bust. They eventually bought Clean Mobile, including all of the patents and most of the employees. As a result, TQ also got their hands on an e-bike motor – which, interestingly, they’d largely developed anyway.

What’s special about the HPR 120S motor is its enormous power with 120 Nm of constant torque and its compact size. Having so much performance in a package that takes up so little space isn’t standard fare for e-bikes and it was achieved through Toni Rossberger’s pin ring transmission design. For TQ, the concept of compactly packaged, high-efficiency design is something of their hallmark – especially in robotics, and it’s the approach that retains their standing as a high-end company focusing on quality over quantity.

Since the HPR 120S motor entered the market in 2012, it has kept a relatively low profile – something that TQ actively wanted.

The Bavarians deliberately opted for a low-key entrance rather than hammer the motor onto the market, as this gave them the flexibility to monitor its quality and step in should any teething problems occur. As a result, the motor has so far only been used on bikes from M1 Sporttechnik, and when it does go mainstream and up its production numbers, TQ can be confident that there won’t be any unwelcome surprises.

Yet the motor is just one part of a system that TQ has developed. Like in other industries, the brand takes on the role of being a development partner too. The eMTB segment has existed with two types of motor suppliers: those offering a completely closed system that doesn’t allow any freedom to the bike brands to customise the system; or those that are completely open allowing the bike brand to configure everything from the display to the motor or the battery. The downside to these systems is the confusion when something goes wrong: just who is responsible? With such haziness, the customer is usually left waiting with an indeterminate time for repairs or replacement parts.

The company is working collaboratively on a robot known as Franka Emika, which has already won the German Future Prize, as well as money counting machines for banks, and ticket machines for train stations.

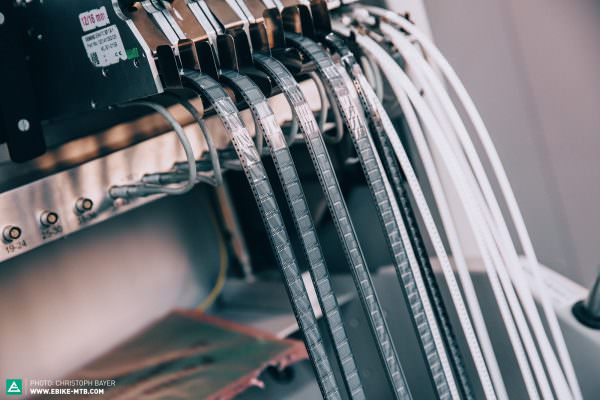

This is where TQ cover all the bases by working closely in their partnerships, ensuring joint development, production, assembly and – ultimately – accepting responsibility. Right now, the company is working collaboratively on a robot known as Franka Emika, which has already won the German Future Prize, as well as money counting machines for banks, and ticket machines for train stations. For the bike industry, TQ will do the same: from the display to the controls, from the battery management system to the motor, TQ will develop, produce and supply the parts. When the company is aware of a gap in its know-how, they know exactly where to turn, seeking out reliable partners – each time, knowing that the liability will always fall on their shoulders. Most recently they outsourced support for the development of their own app.

The Haibike FLYON models represent the first bikes sporting TQ’s know-how, and it’s the first chance for the public to really try the system out. These bikes, however, are engineered to be more than just a frame with a powerful motor. With input from TQ, Haibike have revised their approach to integration, design and usability and the Flyon range represents the fruits of that labour. At EUROBIKE the sight of these models caused a stir, prompting other bike brands to reach out to TQ in the hope of future collaborations.

Naturally, such a positive reception could have resulted in a huge number of orders for TQ, but they take a more conservative approach, only accepting projects that they are confident can be successfully carried out. For the Bavarian-based team, it’s the Technology and the Quality that truly count.

More info at: tq-e-mobility.com

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of E-MOUNTAINBIKE, you will help secure a sustainable future for high-quality cycling journalism. Click here to learn more.

Words & Photos: