A look behind the scenes and into the future, as well as the really important questions driving the Specialized Turbo Levo development team: what turns engineers into interior designers and why are the brains behind the Levo at least as egocentric as they are ingenious?

We’re located 9,400 km east of Specialized’s headquarters in California to take an in-depth look at the development of the best eMTBs of 2018 and 2019. Welcome to Switzerland! More specifically, tranquil Cham where Specialized’s ebike development centre is located and the birthplace of the Turbo Levo.

Cham, 8:30 a.m.: we turn into the 400-year-old site of the old paper mill. The 1960s industrial charm and the turquoise blue river Lorze will make the heart of any lost place photographer or Instagram influencer beat a little faster. You wouldn’t expect this to be the development headquarters of one of the most important eMTBs on the market. An unmistakable hint is the impressive, matt-black gates with its glossy Specialized lettering. Separated from the river, the building once housed the workshop of the paper mill. Built in 1957, it is one of the most modern buildings on the site. After Papieri Cham relocated their production to Italy in 2015, the 120,000 m² site gradually became populated with apartments and office space. Specialized’s development team moved here in 2016, immediately after the renovation work was complete. “We drove to the hardware store every day,” the team’s developers recall when they were moving in. And even 3 years on you’ll still find construction machinery and building materials in the corners. Today, the old cargo cranes continue to bear witness to the site’s past, hanging over the halls like ghosts of days long forgotten. Here and there you’ve got parts of the old wall and glass fronts that separated the offices from the workshop on the ground floor.

As if the city was made to be the birthplace of the Specialized Turbo Levo, Cham received the European Energy Award in 2012, making it one of the few communities in Switzerland committed to sustainable energy and environmental protection. The electricity for the site of the former paper mill is generated from the Lorze as well as solar panels on the roof. “We wanted to be at the centre of the ebike boom, to be as close to the riders and the market as possible. This is enormously important for product development, so, naturally, Germany, Austria and Switzerland made for obvious possible locations. Since we already had a branch office in Switzerland, we eventually settled there. ” – Dominik Geyer, Global Business & Marketing Manager.

Going through the main entrance, you arrive at Specialized’s private Levo museum. From Specialized’s original Turbo with hub gears and a belt drive to the first Turbo Levo prototypes, first generation Turbo Levo’s and up to the Turbo Kenevo, you’ll find all the electric milestones gathered here. However, it’s not the collection of bicycles that’ll grab your attention first, but the details on an extravagant looking RV that has taken the long journey from America to Switzerland. Affectionately referred to as the “Happy Camper,” its a side project of none other than “design guru” and company legend Robert Egger. Along with functioning as a space for 1:1 meetings, the employees are free to enjoy the peace and solitude of the “Happy Camper” after a hard day’s work.

From mountain bike to eMTB – from Stumpjumper to Turbo Levo

Things get even more exciting beyond the “Restricted Area!” sign. According to Specialized’s long-standing philosophy “Innovate or die”, this is where ideas and concepts come to life that will determine the future of our sport in the coming years, whether it’s new shapes and lines flowing from the designers’ pens, or geometries and motor concepts from the minds of the developers. There are around 24 designers, engineers and developers working in Cham with the sole purpose of creating the best eMTBs available on the market, successfully, as the results of our 2018 and 2019 group tests can attest to. Only what is firmly anchored at the core, can manifest itself externally: The Specialized guys live ebikes, perfectly situated at the epicentre of the market with an office that reflects their work ethic and their high demands of the products they create. Although Specialized is a billion-dollar corporation, the Californian brand is still able to find a holistic approach. Marketing and branding are more than a superficial promotional measure here. The concept stays true to its driving force behind – if the product is right, then the rest will take care of itself.

“No bike leaves our development centre until we are proud of the product and it’s earned the right to bear an ‘ S’ on the head tube, says CEO Mike Sinyard. The designers’ pride is literally displayed on their walls. Wherever there is a free spot you will either find a huge Specialized poster or a signed and framed jersey of one of their hitherto non-motorised team riders.

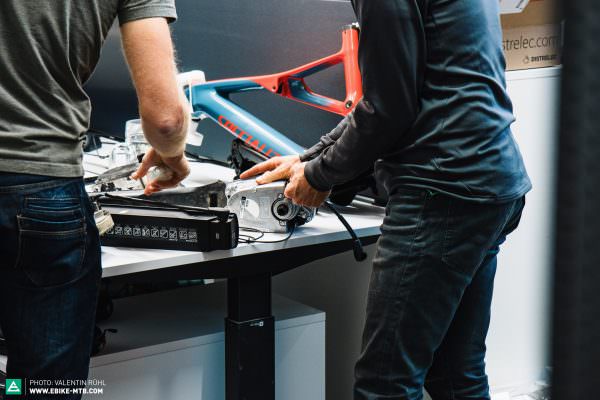

On the desks everything screams eMTB – here a motor, there a battery, or a switchboard, or a complete Levo, ready for the lunch ride at 12:15. We can’t resist going for a ride on the local trails with Marco Sonderegger, Turbo Product Manager, and Jan Talavasek, Turbo Engineering Director. As befits a true developer, Marco uses his smartphone to optimize his Turbo Levo on the way to the summit: “Shuttle Mode 40%, Stealth Mode on, Battery Peeper off, Turbo 100% / 100 Peak, Trail 50% / 100 Peak, Eco 30% / 30 peak, Acceleration 0% .” As steep as the north face of the Eiger and crisscrossed with roots, the trails on the other side of the hill are anything but easy.

Mountain bikers build mountain bikes

And damn, the guys are fast! Once at the bottom, the broad grins on their faces speak for themselves. “We build the best bike for ourselves,” Jan’s eyes brim with euphoria, and that’s exactly how we feel as we walk through Specialized’s halls in Cham. The people who work here create bikes they love to ride. The bikes are the result of a lot of hard work, brains and a big dose of passion, evident in every gesture and conversation about the Levo. “My favourite detail? Difficult to say, the entire bike is full of them. What I still see as the biggest added value is the modular cockpit. With the Levo, everyone can configure the cockpit to suit them exactly. From stripped back to full-on game console…” Jan puts it in a nutshell.

My favourite detail? Difficult to say, the entire bike is full of them. – Jan

If we want something you can’t buy, then we build it ourselves, just look at S.W.A.T. – Marco

We are confident that the range of eMTBs on the market will continue to diversify. – Dominik

The Specialized Levo team works hand in hand with their suppliers to ensure that what they create will ultimately be the best eMTB. This enables them to match every component perfectly. It is for the same reason that the software and motor characteristics of the Brose Drive S Mag has been specially adapted and tuned to suit the Specialized Levo.

The ebike market will remain exciting,” Dominik is sure. “Both on the bike and on the technology side, innovation will continue. At the same time, we are convinced that more and more riders will find their way to eMTBs and that the range of eMTBs on the market will continue to diversify – be it in terms of power, range, weight or intended use.

This article is from E-MOUNTAINBIKE issue #016

E-MOUNTAINBIKE Magazine is published in a digital app format in both English and German. Download the app for iOS or Android to read all articles on your tablet or smartphone. 100% free!

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of E-MOUNTAINBIKE, you will help secure a sustainable future for high-quality cycling journalism. Click here to learn more.

Words & Photos: