Hardly any other bike brands have as much ebike development capacity as the US giant Specialized. But what does it mean to develop your own motor system, and what advantages does this offer the end user? We had the exclusive opportunity to visit the Specialized Turbo development centre in Cham, Switzerland to find out, and we didn’t pass up the opportunity to test the latest bikes and features, and hit the trails with the brains behind the Turbo Unit.

Modern eMTBs have come a long way, transformed from ugly ducklings to sexy, high-tech machines for a wide variety of applications. The era of rudimentary frames, cobbled together with outboard motors, batteries, and remotes is long gone, and the demands of customers – and the industry – are growing at a rapid pace. As such, so are the unique selling points, because brands must stand out from the crowd, presenting a holistic product that can do more than just perform well if they want to be successful, especially in the premium sector. User experience has become the new buzzword in recent years, and it also applies to eMTBs!

From paper mill to Turbo Unit

Charm, Cham, style & innovation: the Specialized Development Centre in Switzerland has it all. The Turbo Unit is housed in the building of an old paper mill, which was built in 1957. The building’s high ceilings leave more than 70 developers from 15 nations with plenty of room for creativity and wild ideas. We were welcomed by a whole regiment of Turbo employees, guided through the headquarters and along the trails by the “Leader of Turbo” Dominik Geyer – whose title we’re admittedly a bit envious of – and the “Director of Turbo Experience” Marco Sonderegger, among others. Unfortunately, “Senior Director of Turbo Innovation” Jan Talavasek couldn’t be there – we would have loved to pick his brains over a piece of delicious cake, but hopefully we get invited back so we can catch up on that ;). We also got to hang out with “Leader of Category Management” Dennis Rankl, and Mattia Berardi – who is responsible for the new eSUV Tero X – during our visit.

The work of the Turbo Unit covers Specialized’s entire ebike portfolio, ranging from electric road bikes like the Turbo Creo SL to eSUVs such as the new Tero X and the classic Turbo Levo eMTB. So, the building is a treasure trove of everything to do with Specialized ebikes, along with countless souvenirs like the first Turbo Levo prototypes, the first Turbo motor and several components that never made it to production. In addition to jerseys from legends of the sport such as Loic Bruni and Peter Sagan, there are crazy drawings of Lego figures and a slightly dusty “Innovate or die” trophy. The latter can be won in Specialized’s internal competition by the most innovative department. However, it’s been awarded to the Turbo Unit for the last 4 years straight, and they don’t intend to give it back anytime soon.

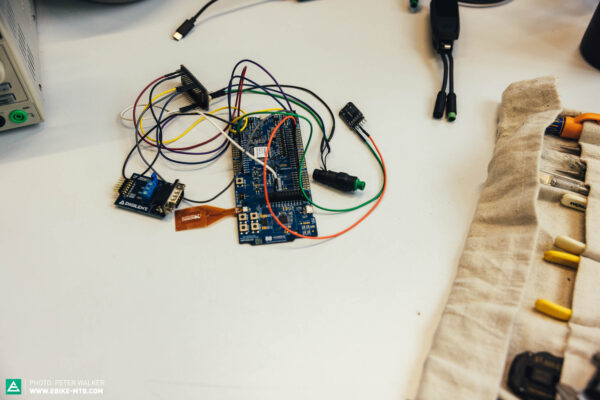

The rest of the building also has a certain Cham… we mean charm. Between photos of old parties, the office dog, and a host of various private pictures – sorry for publishing – the desk is covered with the wildest tech gadgets and the world’s latest ebike developments. It’s definitely got more character than the clinical atmosphere we’ve experienced at the headquarters of other bike companies.

A view of and a grip on the big picture

Specialized already set new standards with the first-generation Turbo Levo, and they’ve adopted a unique approach amongst bike brands. According to their own company motto “Innovate or die”, they have taken the development of the motor and software into their own hands. By doing so, the Californian brand haven’t just created an exciting and unique sales proposition, but also given themselves the opportunity to respond to very specific requirements. This means that they can act independently of the development focus and speed of the big suppliers, and they’ve got sovereignty over the data and knowledge gained from their customers, not to mention the entire process from development to sales. After all, knowledge is power. And in this context, the collected data – if used and analysed correctly – enables optimised product development that more accurately meets the needs of customers. In addition, you can identify problems and use cases that you may not have been aware of or add features that improve the much-touted user experience.

Specialized recognised this potential early on, opening the so-called “Turbo-Unit” in 2010, its ebike development centre in Cham, Switzerland. Central Europe is the heart of the e-bike world, considered to be the driving force of the e-boom. Therefore, it was a strategically smart decision to set up an ebike development centre here, even (or perhaps especially) as a US company. Greater proximity to the primary market, which is a few years ahead of other markets in terms of development, allows for more inspiration and innovation, as well as product feedback.

The fact that everything is done in-house has obvious advantages for the customer. This allows for a more seamless and coherent interaction between the individual components. Everyone involved in development knows from the very beginning what the parts look like and what their requirements are. There’s no struggle to find common standards and keep the product generic and universal to serve the widest possible range of bike brands, the way the big motor suppliers must do. Rather, Specialized can develop products that are specifically tailored to their own requirements. At the same time, this enables a higher level of integration since the individual components can be designed to work with one another before building the frame, for example. That way, Specialized can create tailor-made solutions, while other bike brands must work around the solutions provided by motor manufacturers, which are usually intended for an extremely broad category, covering vastly different products. For after sales service, you know who to contact, because everything comes from the same company. This was particularly relevant with the previous generation Levo which had frequent issues with the belt of the motor. Specialized claim to have learned from these problems, which we were able to experience first-hand during our visit to Cham.

Apart from the obvious benefits, there are some other things that become apparent only on second thought, but still offer clear advantages to both the end users and Specialized. To get to the bottom of exactly what these are – and much more besides – we spent two days in Cham to have a chat with the brains behind the Turbo Unit. We didn’t just talk about the future, but also had a look inside the crystal ball, even though Specialized got rid of any traces of prototypes that we weren’t yet allowed to see in preparation for our visit. We discussed current market developments, considered the future of eMTBs, and exchanged exciting ideas. And of course, we didn’t miss the opportunity to sample the local trails aboard four Turbo Levos and test the new Specialized Tero X eSUV exclusively for you.

Why stick to wheat if there are other grains?

The last few years and the global political landscape have clearly shown what it means to be dependent and what effects this can have. This dependence has affected many bike manufacturers, especially during the pandemic, because building a bike usually involves a lot of different manufacturers. The frames, suspension, motors, batteries, brakes, tires and many more components come from different factories, and some were available while others just weren’t. With the latter, bike companies had to quickly find alternatives or risk sitting with tons of unfinished bikes collecting dust in their warehouses instead of making waiting customers happy. Specialized, on the other hand, have long been doing things themselves, bringing components such as wheels, tires, and handlebars in-house. Their in-depth, in-house development has proven to be particularly advantageous in the case of e-systems and has allowed for quick and unconventional solutions. For example, in the event of an availability-related change in the chip or battery supplier, they can easily adapt the firmware and software accordingly, since this know-how comes from the company’s own ranks. Those who bake their own buns can be a bit more creative with the ingredients, still selling buns when others have run out of wheat.

The Turbo Unit at its own pace

Those who are less dependent can better pursue their own agenda: Specialized aren’t dependent on the development speed and cycles of other manufacturers due to their holistic approach, and they can ultimately decide for themselves when a component, software update or system has reached market maturity. If a manufacturer supplies several brands, it can happen that their customers, i.e. the bike companies, put pressure on the development speed, making them release products onto the market that haven’t yet reached the maturity necessary to do so – as our big 2023 E-MOUNTAINBIKE group test of 30 eMTBs has shown. Keeping things in-house also allows a company to cater more to their own and ultimately their customers’ needs, so they don’t have to accept any compromises in this regard or play second fiddle to larger companies with more purchasing power. Nevertheless, there is a catch: despite in-depth development and a holistic approach, there’s a continued dependence on motor manufacturers. Specialized don’t manufacture their own motor, but rely on development and production partnerships with Brose and MAHLE instead. If they encounter problems or the product idea doesn’t work as expected, it must also be readjusted and improved, of course. Nevertheless, Specialized have a better grip on the development pace than many other bike brands, which usually have little to no influence over the motor manufacturers.

Big data

Big data offers big opportunities, but it’s a sensitive topic, especially in Europe. However, most of us have been disclosing the data of our everyday lives for years now, knowingly or not. No matter if it’s via your smartphone, online shopping, or the loyalty card from your local cafe: large datasets can contain invaluable insights. Once anonymised, they can help identify product issues, new use cases, and usage statistics, and align product development much more closely to customers’ needs. Of course, this also applies to (e)bikes. With the help of Specialized’s Mission Control app, more than 155 million rides have already been recorded, collecting an incalculable amount of data. Evaluating it is a complex and time-consuming task. But it doesn’t just allow Specialized to know who is riding, for how long, and on which trails, but also how fit you are or which support modes you prefer using on which bike. They can also collect data on charging stations, charging cycles and service requests, and clearly show whether or not Specialized riders prefer to leave their battery in the bike for recharging, for example. In the future, all this data will be linked to the data collected by bike shops, revealing when bikes get shipped, bought, and activated, or how often and why they get taken back to the dealer. If all these data sources are linked, previously unknown problems can be identified, processes optimised, and it can drive future-oriented development that is very much in line with the customers’ needs. At the same time, it gives Specialized a clear competitive advantage. Working with systems from external suppliers, the competition usually don’t have access to these kinds of data, and the motor manufacturers are reluctant to share it, especially with regards to problems.

Make it work or “the best continues to get better”

What exactly do riders stand to benefit from Specialized’s company strategy of taking everything into their own hands? During our visit, Dominik Geyer repeatedly dropped the phrase “the best continues to get better” and he means it literally. Specialized have been regarded as drivers of innovation in the bike industry for many years, regularly setting new standards, which then gradually get accepted by the mainstream. For example, Specialized integrated their MasterMind display into the top tube years ago, creating a trend that is now starting to bear fruit. Many brands are following suit and implementing this type of integration in their latest generation ebikes. Specialized also pioneered the battery removal system on the Turbo Levo, the integrated storage compartment in the down tube, and tools in the headset, all of which are things other brands have now caught on to and copied. With their latest software, Specialized are blazing their own path once again, gamifying trail riding by recording the distance and height of your jumps in the Jump Stats – like on Zwift but in real life. And although the latest generation Turbo Levo has been around for more than two years – which is a very long time in the eMTB world – it can easily keep up with the latest competition in many respects, including integration and connectivity, even if it lags behind in terms of the motor’s size, for example. And even though we couldn’t spy any new highlights during our two days in Cham, there was a clear sense that the Turbo Unit hasn’t been asleep, and they have no intentions to sweep the dust off the “Innovate or die” trophy.

Due to their in-depth development and vast know-how, which belongs to Specialized, not a supplier, they have a completely different foundation for future developments and features. In addition, it’s up to them to decide when something is ready for the market. Thus, according to their own statements, they won’t release any (more) systems onto the market that aren’t mature, having learned from past mistakes. They say the same applies to software updates – which are extremely complex, by the way: typically, Specialized test 150 different versions before they can be sure that a software update will work on all products available on the market. Every product variant and supplier must be factored into the tests, and just because the hardware is already on the market doesn’t mean that it can’t be improved upon. As with smartphones, we must get used to the fact that software updates can add new functions, although the hardware remains the same.

We are convinced that the range of E-MTBs on the market will continue to diversify.

-Dominik Geyer

When we first visited Cham in early 2019, Dominik said: “We’re convinced that the range of eMTBs on the market will continue to diversify.” On the one hand, everything becomes more specialised (excuse the pun), but also more accessible to the broader masses. Everything is getting more customised, or customisable, and tailored to the end user. As we’ve been saying for years, the best bike is the bike that best suits your requirements – which you can figure out with the help of our interactive buyer’s guide. However, this is only possible if bike companies prioritise it, but they all have different philosophies, and each brand must decide for themselves what brand promises they make and how they plan to keep them.

Not all of them will take this path and go these extra miles. But maybe that’s why “special” is a part of Specialized’s brand name. That said, the advantages are there for all to see.

Our visit to Cham didn’t reveal any world firsts, and yet we were very impressed. Especially with the depth of development and the lengths they go to, which is quite unique for a bike brand. We love their development approach of continuously improving existing products, instead of shortening product cycles, and Specialized have built a rock-solid foundation on which they can go even more Turbo in the future. True to the motto: long-lasting enjoyment over short-lived consumption.

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of E-MOUNTAINBIKE, you will help secure a sustainable future for high-quality cycling journalism. Click here to learn more.

Words: Peter Walker Photos: Peter Walker