Taiwan is the unofficial centre of the global bike industry and is home to some of the largest and most well-known manufacturers. But what exactly does that mean? We had the exclusive opportunity to accompany the development process of the new MERIDA eONE-SIXTY and have learnt a surprising amount at the headquarters of the second largest bike manufacturer in the world.

“I do not say no anymore. I do not know what will happen” is one of the most memorable statements made by William Jeng, Senior Vice President of MERIDA during our visit. We had been greeted with a cup of Taiwanese Oolong tea, but several cups later, our “quick welcome” had turned into an insightful discussion about the company, the “Made in Taiwan” label and MERIDA’s philosophy around work.

We have to be honest that we didn’t know that much about MERIDA, what they stand for and what the production plants in the Far East would look like. But let’s not get ahead of ourselves just yet and start with the basics. What does MERIDA stand for?

Me-Ri-Da – the story about MERIDA only few people know

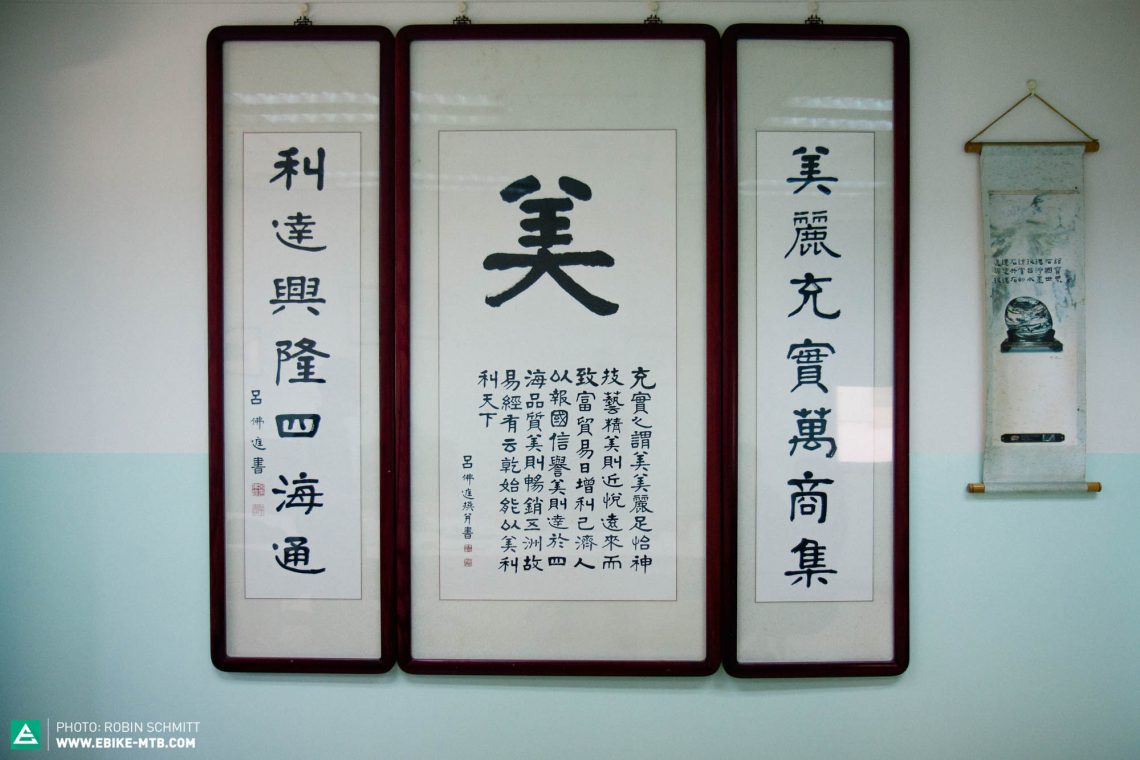

If (like us) you thought MERIDA got their name from a city in Spain or Mexico, we have to disappoint you. Me-Ri-Da is composed of three Chinese syllables: “Me” stands for beautiful, “Ri” stands for comfortable and “Da” stands for fluid and mobile, particularly in terms of vehicles and transport. Roughly translated then, Me-Ri-Da stands for “The production of beautiful, high-quality products that allow everyone to reach their destination in the most pleasant way possible.”

The fact that founder Ike Tseng initially focussed MERIDA’s attention on producing motorcycle parts in its early years clarifies the idea behind the company name. Ike developed the company into a bicycle manufacturer relatively quickly thereafter, initially working with Raleigh Bikes, though many other western bike brands soon followed. Today, MERIDA only produces bikes for a handful of other companies. Since the 1990s, the Taiwanese company has been pushing MERIDA as its own brand and started sponsoring its own teams at the start of the new millennium, including Multivan MERIDA, Lampre-Merida or today’s BAHRAIN MERIDA Pro Cycling Team. Attesting to the success of MERIDA’s engagement in the sport are the Olympic and World Champion medals on display in the company’s entrance hall.

Today, the company is managed by Ike’s son, Michael Tseng, and now employs around 4,000 people worldwide. In addition to its headquarters in Yuanlin, south of Taichung, MERIDA have three more factories in mainland China. To put that in context, about 1,300 employees work at the Taiwanese headquarters alone, capable of producing approximately one million bikes annually. Anyone who is more familiar with MERIDA’s product range knows that they’ve come a long way in the last five years, with a large and coherent product portfolio ranging from road and gravel bikes, to urban and mountain bikes. The most recent and also most successful segment added to their portfolio is their eMTB range. The ebike division already accounts for 30% of MERIDA’s total sales.

While production and manufacturing is based in Asia, MERIDA’s development centre, including an assembly line for the European market, is located in Germany. MERIDA have a unique advantage in being able to combine German development expertise with in-house production and manufacturing experience in Asia. This, paired with the ability to coordinate teams across different time zones and maintain a close and collaborative relationship between them, is MERIDA’s key to success.

Designed in Germany, Made in Taiwan

But what does this collaboration across national and cultural borders look like? We followed the development process of the new MERIDA eONE-SIXTY to find out.

Since the first generation of the eONE-SIXTY was a huge success for MERIDA, the first question the developers asked themselves was “what, if anything, do we want to change?” And so the designers’ goals at the development centre in Magstadt, a tranquil municipality near Stuttgart, slowly crystallised. On the agenda was a slim, integrated battery, carbon fibre main frame, noise reduction, distinctive design features and refined geometry for even better trail performance.

In general, the development of an ebike depends heavily on the range of available motors and batteries. There are hardly any bike brands big enough to develop their own motors capable of delivering a similar level of performance as the competition and, above all, to guarantee a reliable, worldwide service network. MERIDA already had a close working relationship with Shimano, so it was obvious who they were going to partner with to accomplish their vision for the new eONE-SIXTY. There was one problem though: when MERIDA started on the development of the new eONE SIXTY, Shimano had no compact internal battery to match MERIDA’s vision. So the development team from Magstadt worked out blueprints for a new battery and the foundation for the new Shimano STEPS BT-E8035 battery was laid.

The frame and features such as the battery cover or the distinctive Thermo Gate at the head tube are designed in Germany and then validated by the team in Taiwan, who determine suitable manufacturing processes and what is feasible in terms of cost and whether the product can be mass-produced while meeting quality standards. There are around 20 Taiwanese engineers at MERIDA’s headquarters to ensure that the requirements of the German development team are properly implemented in production – no small feat with more than 700 models in their portfolio. After some back-and-forth between Taiwan and Germany, the concept goes all the way from initial geometry sketches to 3D models and first prototypes, eventually approaching the final design. During this time, the German development team occasionally works on site in Taiwan to address problems and clarify the finer details as well as to maintain business relations with their suppliers and development partners. During our visit to Taiwan, we also had the opportunity to attend a meeting with the tire manufacturer MAXXIS and were able to visit the factory where all MAXXIS bicycle tires are made. Incidentally, the headquarters of MERIDA and MAXXIS are in the immediate vicinity, along with many other manufacturers in the industry. Even though it is hardly perceived as such by everyday cyclists, Taiwan is undoubtedly the unofficial centre of the worldwide bicycle industry. Many of the largest manufacturers, who supply many of the bike and component brands we know, are based in Taiwan.

Even though it is hardly perceived as such by everyday cyclists, Taiwan is undoubtedly the unofficial centre of the worldwide bicycle industry

Taiwanese-German corporate culture

We admit it – we used to associate working conditions in the Far East with long, drill-instructor style, exploitative shifts. But at MERIDA, we encountered a very different picture. The working atmosphere feels positive, harmonic, and they’ve got the right mentality. Just-in-time production, in particular, requires a high level of flexibility from the employees as well as a sense of responsibility and the ability to quickly grasp and manage complex processes.

Under increasing competitive pressure, many Taiwanese manufacturers, including MERIDA, started moving their factories to the Chinese mainland years ago. However, there’s an increasing move to other Asian countries, as labour costs are now rising in China too.

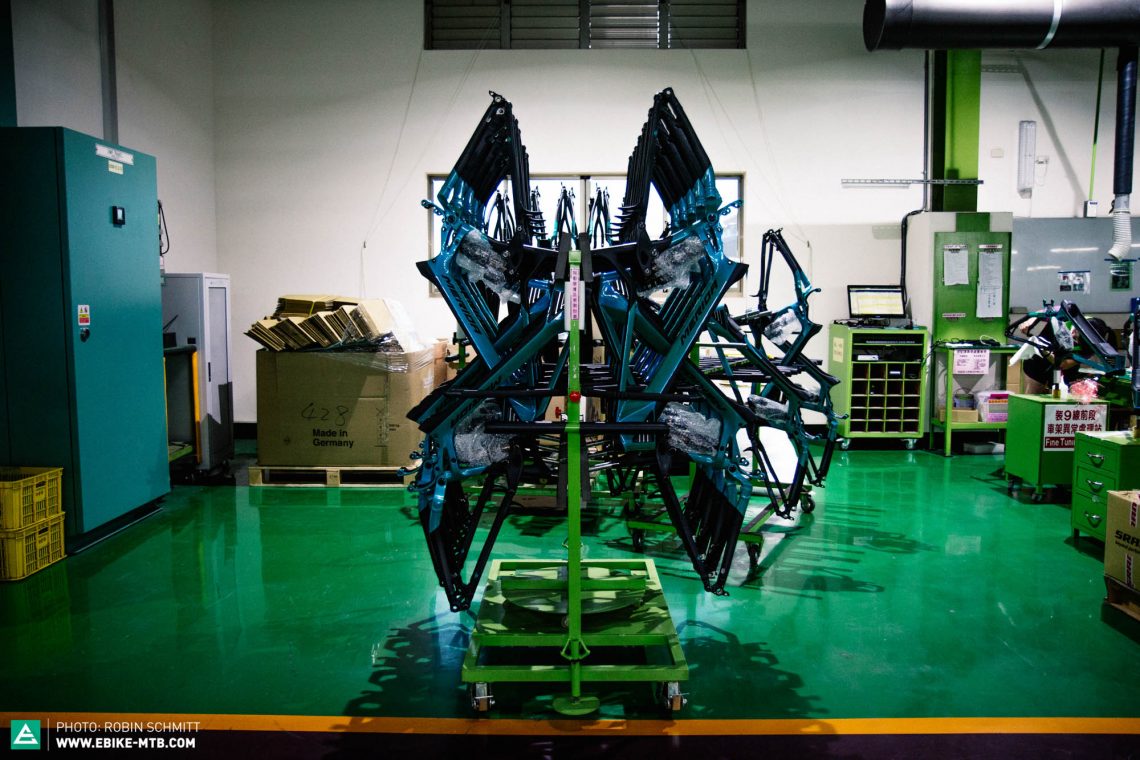

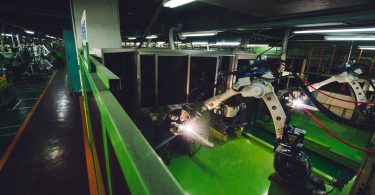

We only gained an insight into the factory at MERIDA’s HQ, but can tell you what we experienced there: In the organically grown factory halls with all its nooks and crannies, you’ll find state-of-the-art CNC machines, with robots doing the welding and, in between, a lot of skilled manual labour. You can still identify which parts of the factory are older and which are newer, allowing you to see something of how MERIDA’s processes have changed over time.

Long-term cooperation with both its employees and business partners is very important to the Taiwanese manufacturer. How have MERIDA achieved this positive working environment and such good teamwork? William explained it to us during our third cup of Oolong. Empowerment, in this case the transfer of responsibility to the employees and the flat organisational structure is one important pillar. It allows employees to engage and implement their own ideas, which works best without the strict measurement of one-dimensional performance metrics and by giving each individual room for creativity and action instead. However, it is expected that ideas and input are discussed openly with the staff concerned before making a decision in order to achieve the best possible result. If the managers have a positive attitude, then this has an effect on the entire company. There is also a bonus system for the employees allowing them to participate directly in the company’s profits as shareholders.

“People make mistakes, I make mistakes, you make mistakes… that’s human and should not cause any headaches” William tells us in a down-to-earth tone. His statement stands in stark contrast to the hire-and-fire mentality of many American companies.

Traditional Asian wisdom and MERIDA as an ebike pioneer of the 90s

The positive attitude is not only visible during work, but also in the strictly observed breaks, where employees joke around or, just like everyone else in the world, keep themselves busy on their smartphones.

The traditional calligraphy on the factory walls express the Asian teachings that are manifested in day-to-day life at MERIDA. Opposite the company premises is a temple, dedicated to the patron god of the country. The company building itself is aligned in accordance with Feng Shui – a flowing river in front of the entrance and a small mountain at the back are said to provide good energy and help the company prosper. Incidentally, the mountain served as a testing ground for the first ebike that MERIDA developed entirely by themselves, which we were also allowed to ride during our visit. The bike was developed in the 90s, from the frame to the control unit and the battery up to the torque sensor.

“It was an adventure, no one knew where the road would go” William explained as we discussed how they approached the project back then. But even though it was given several design awards, success was still a long way off. The market was too small, some components couldn’t be produced in sufficient quantities and the marketing and distribution weren’t yet up to scratch. Although the legislation for ebike mobility was in place, the opportunities remained undiscovered by potential customers due to a lack of information. “But we always believed in the idea that sometimes you just have to be a pioneer.” Williams’ eyes shine as he says it – no trace of regret over wasted resources, but an awareness that the times constantly change and that experience gained always pays off someday.

The Taiwanese company has always been quick to adapt to new demands and challenges. Case in point, setting up an ebike production site within six months, which now has an output of around 900 ebikes per day, whilst operating within the different requirements of 40 countries, each with their own regulations and software requirements.

Benjamin Diemer, Senior Product Manager for ebikes, still remembers those times well. He had been hired as the ebike Product Manager, but there was no ebike production yet. On his first visit to Taiwan, he was led to a back door of the existing factory which opened onto a green field and told that this was where they would be producing ebikes half a year later. Which is exactly what happened – from then on, he knew that he could trust MERIDA to not only talk but also to act on their words! This trust is shared by the employees at the headquarters and over 20% have been working in the company for more than 20 years.

What about the eONE-SIXTY? After extensive laboratory tests and test rides on prototypes made by the German development team in Europe, several rounds of improvements followed before the bike was allowed to go into production. MERIDA have very strict quality standards and prefer to play it safe. “It can be frustrating at times,” Reynaldo Ilagan, Head of Product Management, told us. “Often you have these great ideas that are technically feasible, but then they don’t meet our Taiwanese colleagues’ stringent criteria. And sometimes you see how your competitors create products for which they’re celebrated, but we wouldn’t be able to make anything similar because of the high standards we set ourselves.”

During our visit, the first pre-production bikes were being built for the official presentation while the assembly team was being inducted into the new production process. MERIDA take a lot of pride in their production competence, having adopted the “Kaizen” principle from Toyota 20 years ago which focuses on the continuous improvement of processes and products. Even if this production know-how may not sound all that important, it is absolutely critical. Most bike brands don’t produce their own products and depend on outsourced manufacturers resulting in inconsistent production batches, less control or a longer waiting time for their production slot. To understand just how vital production can be, just look at Elon Musk, who referred to the production of the Tesla Model 3 as a kind of hell. A great vision or innovation is only as good as its implementation, hence it is crucial to have a reliable means of production and the necessary know-how.

Made in Taiwan

Our visit to MERIDA Bikes’ headquarters reminded us once again that the world is not quite as simple as we would like it to be – and that we’re not as awesome as we might like to believe! While German automobile scandals have defaced the “Made in Germany” stamp and each country proudly presents its own labels “Fatto en”, “Hecho en”, “Made in”, “Fabrique en”… Taiwan is producing in both quantity and quality. However, whether made in Taiwan, USA, France or Germany, a quality seal is only as good as the manufacturer itself.

whether made in Taiwan, USA, France or Germany, a quality seal is only as good as the manufacturer itself.

While a four day visit is far too short to figure out how a company or a whole country ticks, one of our key takeaways is this: the Far East is not simply the Far East. What we saw at MERIDA positively surprised and impressed us. Not least the hospitality, the respect for each other and the breathtaking tour on our road bike recovery ride to Sun Moon Lake with a little mishap, but that’s another story…

MERIDA is on a roll, and the green rice paddies behind the factory grounds await further plans to expand. What will they produce there? If we had to ask William, he would probably answer, “I don’t know”. Whatever it may be, we have no doubt that it will continue to follow MERIDA’s philosophy of quality. And until then, may the patron god of the land residing in the adjacent temple watch over MERIDA!

Here you’ll find our review of the Merida eONE-SITXY 10K: Exclusive review: MERIDA eONE-SIXTY 10K 2020 – the new benchmark in performance?

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of E-MOUNTAINBIKE, you will help secure a sustainable future for high-quality cycling journalism. Click here to learn more.

Words & Photos: Robin Schmitt