FOCUS have been involved in the E-MTB market for years and offer a multitude of exciting products. Although the great revolution has not yet happened, it’s an imminent prospect.

“For riders, by riders,” surely has to rank as one of the most touted marketing slogans in the bike industry, closely followed by ‘Made in Germany,’ replaced by ‘…the UK,’ or ‘Canada’ to varying frequencies. Virtually every brand takes pride in their origins, their dedicated team and, of course, the resulting products. But the fact is that most bike companies are crammed with hugely enthusiastic mountain bikers at work – it’s nothing new. Thus, catchphrases are flung around so frequently that their meanings are largely lost, and their impact diminished.

At FOCUS, however, they’ve got another, very special USP that they can validly claim: their own motor.

FOCUS is part of Derby Cycles, just like Kalkhoff, Rixe, Raleigh, UNIVEGA, and Santa Cruz, the most recent addition. But what does FOCUS share with the first four companies? Well, they all use their own Impulse motor, which has been designed in-house in Cloppenburg, Germany. Now in its third evolution, there are more than 450,000 of these motors roaming the globe.

The North: Home of production and motor development

As the drive from Stuttgart to Cloppenburg takes six hours, Andi (FOCUS’s senior brand manager) and I have ample opportunity to get to know each other, swap stories, and learn more about the company. After the new year chimed for 1993, the freshly crowned World Cyclocross Champion Mike Kluge began building his own bikes with a passion that later evolved into FOCUS Bikes, Andi explains. The brand grew rapidly before being taken under the wing of Derby Cycles, with the subsequent relocation to Cloppenburg included – where we also eventually arrive.

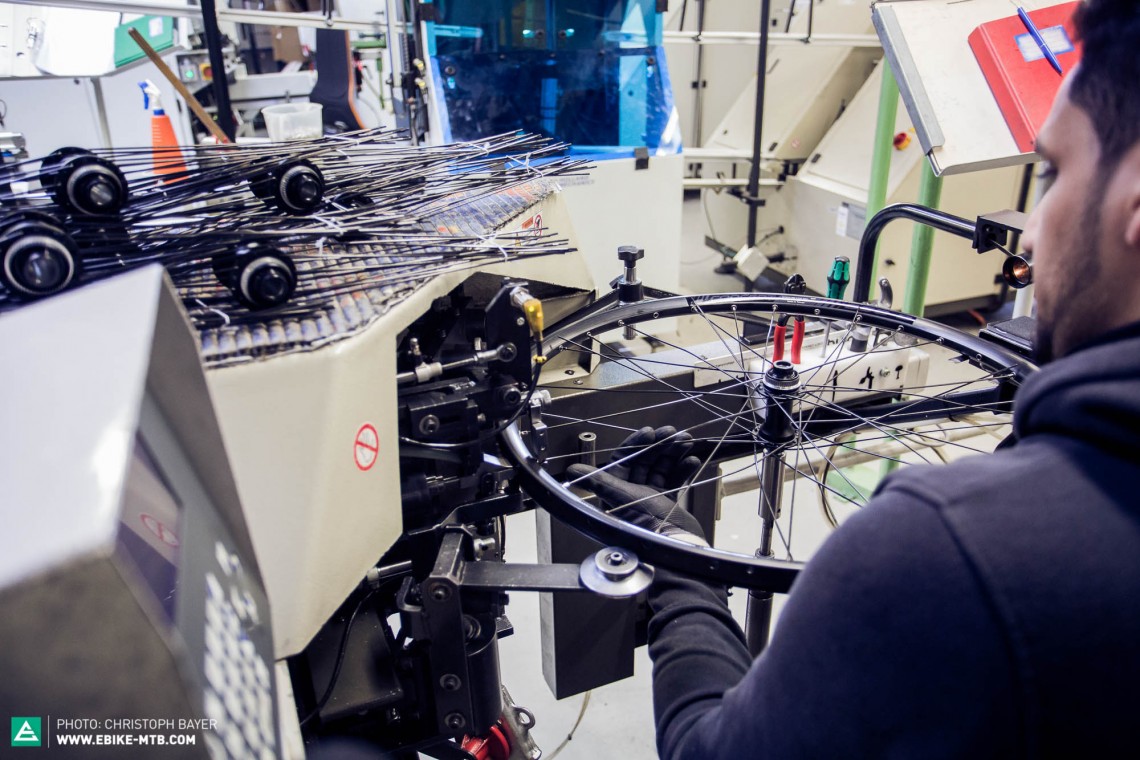

I’m led around from the motor development area to the various assembly stations, where the sheer volume of work that is still carried out in-house surprises me. From finishing the newly-welded frames to the paint job, positioning the decals, and assembling all of the bikes, this all happens in one place – a feat that generates independence and freedom for the firm and allows for more thorough quality control. FOCUS strictly adhere to their high standards of consistency, carrying out random controls on various individual assembly stations, even going as far as having a full test lab on the grounds. Each bike is testament to the work put in: high quality, and individually checked. “One person, one bike,” is the phrase of the day here.

In the impressive red brick building of the former Kalkhoff factory, 500,000 bikes are produced annually, a figure that works out to around 3,500 bikes per day. It’s a huge number, but of course it doesn’t just include E-MTBs.

The South: Home of bike design and development

Despite their huge production numbers today, FOCUS have never lost sight of the importance of identifying with each individual product. A few days after my visit to Cloppenburg I pay a visit to the development office in Stuttgart, where German hip-hop blares out the speakers, dirty riding shoes take over one corner, and there’s a faint trail where ten filthy bikes have been carried down to the cellar (to the dismay of the cleaner). This office, home to sixteen members of staff responsible for marketing and development, is spread over two floors. The presence of helmets on the desks and waterproof jackets on the backs of chairs hints at the fact that the team is made up of undisputed cycling fans, who happen to include two German cyclocross and enduro champions. Shortly before lunch the talk doesn’t revolve around what to eat, but rather which type of bike to use: road bike or E-MTB?

Every bike in the FOCUS collection is designed and developed right here, ensuring that each design holds so much appeal to the team themselves that they are longing to ride each and every sketch.

Now that the world is so inextricably linked via digital means and we’re able to contact each other with the click of a button, the idea of spreading the team across the country isn’t a risk – if anything, it’s a huge opportunity. The creative team at FOCUS have the luxury of enjoying an open and relaxed working environment, they’ve got trails on their doorstep so each prototype can be instantaneously put through the wringer, and in their free time there’s no shortage of culture to discover.

And for proof of the great cooperation between the motor team in the north and the bike developers in the south, the brand new Jarifa Integrale (I29) says it all. With its stylish, integrated 612 Wh battery that’s both powerful and removable, App connectivity and smart details such as the adjustable Shift Sensor, it’s evident just how advantageous the close collaboration is between the bike designers and motor developers. This is where FOCUS can claim their real USP, and it looks likely to be the key to long-term success for the company. FOCUS just need to guarantee that they’ll use it to its full potential!

Check the official website for more information on FOCUS Bikes.

[/emaillocker]Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of E-MOUNTAINBIKE, you will help secure a sustainable future for high-quality cycling journalism. Click here to learn more.

Words: Photos: Christoph Bayer, Sebastian Herrmann, Robin Schmitt